New 3D Printing Material Bends Without Breaking

3D printing service Sculpteo unveiled the Flexible Plastic printing material that yields soft and durable 3D prints.

Here at Tom’s Guide our expert editors are committed to bringing you the best news, reviews and guides to help you stay informed and ahead of the curve!

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Daily (Mon-Sun)

Tom's Guide Daily

Sign up to get the latest updates on all of your favorite content! From cutting-edge tech news and the hottest streaming buzz to unbeatable deals on the best products and in-depth reviews, we’ve got you covered.

Weekly on Thursday

Tom's AI Guide

Be AI savvy with your weekly newsletter summing up all the biggest AI news you need to know. Plus, analysis from our AI editor and tips on how to use the latest AI tools!

Weekly on Friday

Tom's iGuide

Unlock the vast world of Apple news straight to your inbox. With coverage on everything from exciting product launches to essential software updates, this is your go-to source for the latest updates on all the best Apple content.

Weekly on Monday

Tom's Streaming Guide

Our weekly newsletter is expertly crafted to immerse you in the world of streaming. Stay updated on the latest releases and our top recommendations across your favorite streaming platforms.

Join the club

Get full access to premium articles, exclusive features and a growing list of member rewards.

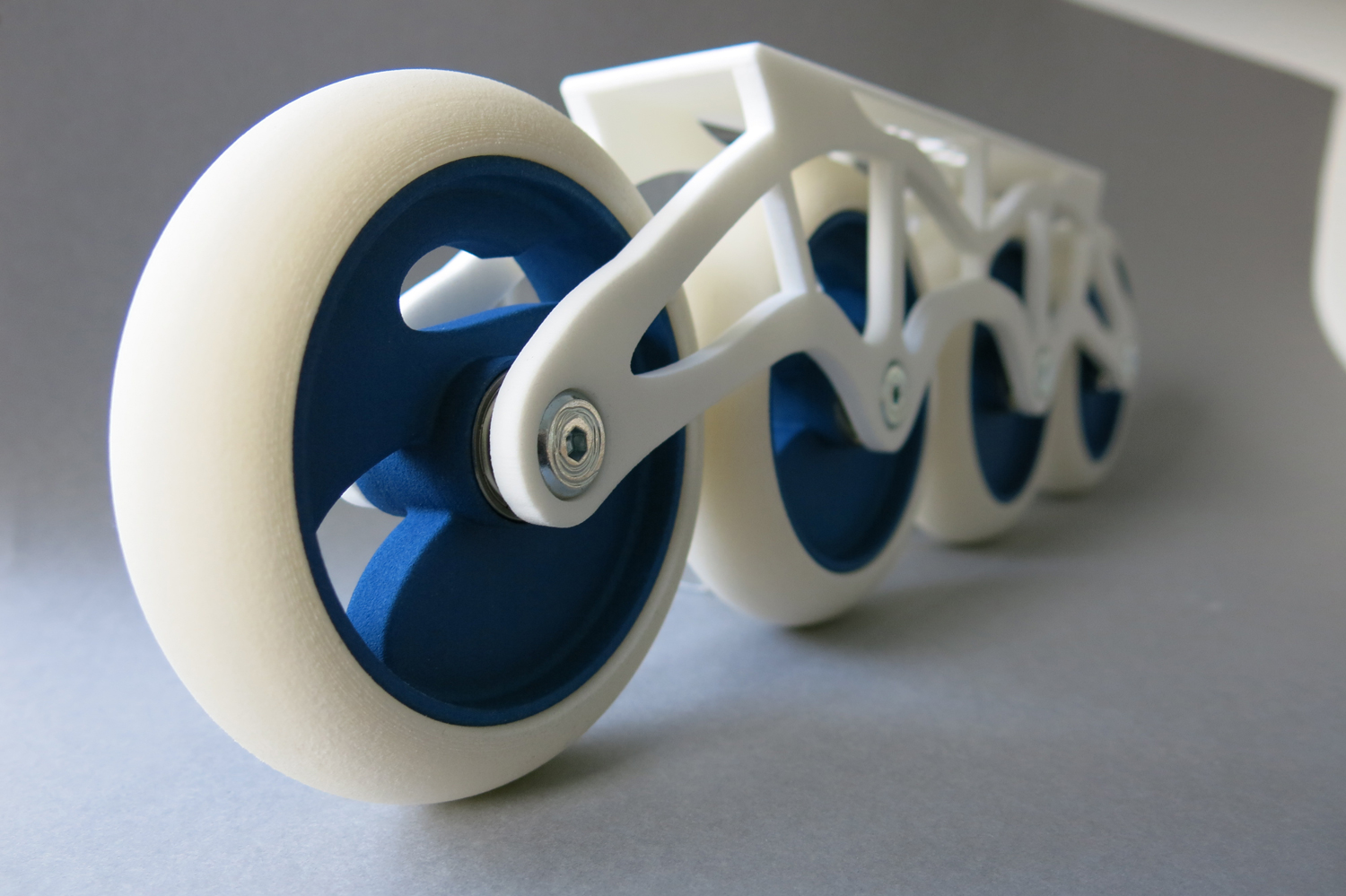

LAS VEGAS — Sculpteo thinks that 3D printing could use a little more flexibility. So the 3D printing service is taking the wraps off a new material that makes its prints more flexible without compromising on durability. The material is called Flexible Plastic, a thermoplastic polyurethane (TPU) that's notable for its ability to produce soft 3D prints that remain functional.

If you're swayed by methods of measuring the hardness of different materials, Sculpteo says Flexible Plastic rates a Shore hardness level of 65A, which is below what you typically see in the 3D printing market.

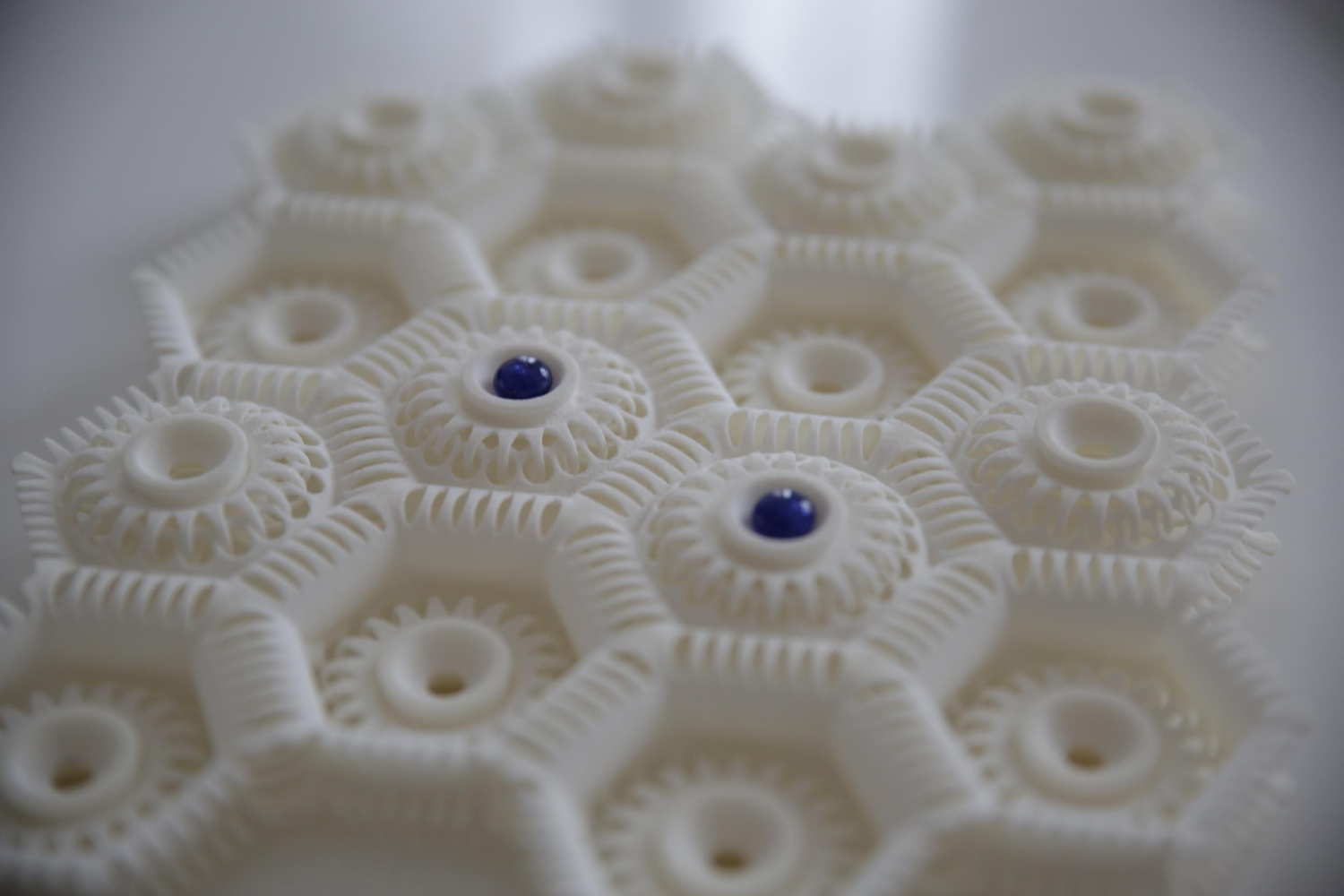

In practical terms, that means items printed with Flexible Plastic will have some give to them. Sculpteo CEO Clement Moreau showed me a 3D-printed model of a human heart made from the material. I was able to squeeze the heart without any fear of it shattering in my hand; I also took note of the intricate details on the surface of assorted arteries and aortas.

MORE: Best 3D Printers

Moreau had a photo of an eve more impressive example of the material's flexibility — a dress printed out of this flexible TPU featuring intricate, interlocking patterns. That's the result of selective laser sintering, Moreau says, which specializes in interlocking patterns.

"It's a completely new way to produce flexible material," Moreau said.

It's also not that expensive, relative to more rigid materials. That human heart model would have cost $80 to print using Sculpteo's service, about the same price as if it had been printed using nylon. There are some constraints on Flexible Plastic, though: you can only produce prints that are limited to 6 x 6 x 6 inches. It also takes a little longer to produce prints with Flexible Plastic, as Sculpteo is taking extra care with the new material. Whereas an order printed from nylon might be ready to ship to a customer in two days, Flexible Plastic prints take closer to a week.

Still, Moreau is excited by what a more flexible, durable material can mean for 3D printing — namely, that 3D printing can expand beyond prototyping into different kinds of manufacturing. Among the types of manufactured goods Moreau believes could be printed with Flexible Plastic are automotive parts, wearables and consumer electronic parts that require material that need to bend or twist without breaking.

- The Biggest Tech Trends: What You Need to Know

- How to Buy a 3D Printer

- 8 Awesome 3D Printing Trends to Watch

Get instant access to breaking news, the hottest reviews, great deals and helpful tips.

Philip Michaels is a Managing Editor at Tom's Guide. He's been covering personal technology since 1999 and was in the building when Steve Jobs showed off the iPhone for the first time. He's been evaluating smartphones since that first iPhone debuted in 2007, and he's been following phone carriers and smartphone plans since 2015. He has strong opinions about Apple, the Oakland Athletics, old movies and proper butchery techniques. Follow him at @PhilipMichaels.

Club Benefits

Club Benefits