New Budget 3D Printer on Kickstarter Produces Huge Projects

The BI v2.0 3D Printer, recently launched on Kickstarter, offers the promise of building bigger objects, with finer detail, than competitors.

Here at Tom’s Guide our expert editors are committed to bringing you the best news, reviews and guides to help you stay informed and ahead of the curve!

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Daily (Mon-Sun)

Tom's Guide Daily

Sign up to get the latest updates on all of your favorite content! From cutting-edge tech news and the hottest streaming buzz to unbeatable deals on the best products and in-depth reviews, we’ve got you covered.

Weekly on Thursday

Tom's AI Guide

Be AI savvy with your weekly newsletter summing up all the biggest AI news you need to know. Plus, analysis from our AI editor and tips on how to use the latest AI tools!

Weekly on Friday

Tom's iGuide

Unlock the vast world of Apple news straight to your inbox. With coverage on everything from exciting product launches to essential software updates, this is your go-to source for the latest updates on all the best Apple content.

Weekly on Monday

Tom's Streaming Guide

Our weekly newsletter is expertly crafted to immerse you in the world of streaming. Stay updated on the latest releases and our top recommendations across your favorite streaming platforms.

Join the club

Get full access to premium articles, exclusive features and a growing list of member rewards.

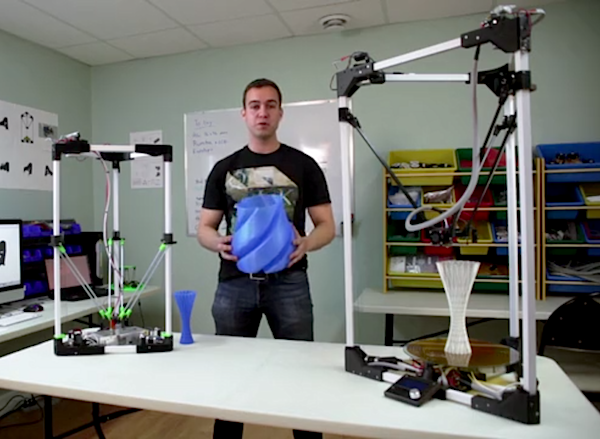

If you are looking to 3D print objects bigger than knickknacks, in a single piece, a machine on Kickstarter may be your answer. The BI v2.0 from Boots Industries is a new 3D printer that has raised nearly twice its $30,000 funding goal in just the first 11 days on Kickstarter.

The BI v2.0 is a so-called delta-style 3D printer, with a printhead attached to six aluminum arms that move the printhead immediately to any position on the item being built — saving time by not having to slide back-and-forth, as traditional 3D printheads do. he BI kit, which requires assembly, will ship in April for about $655. (The creators have stated the price will increase when they sell it online post-Kickstarter.) This is rather inexpensive in an industry where much smaller printers can sell for $1,000 and up.

MORE: Best 3D Printers 2014

The specs that Boots Industries claims for the 3D printer seem to have been designed to exceed those of another recent delta-style Kickstarter project, the Deltaprintr. The BI can print cylindrical objects with a 12-inch diameter compared with Deltaprintr's 10-inch diameter. The BI can do 50-micron layers, which is twice the detail of Deltaprintr's 100-micron layers (the latter being typical of most consumer printers). The BI also supports ABS, PLA and Nylon plastic materials, while the Deltaprintr supports only PLA. Like the Deltaprintr, it uses a pulley system with fishing line to move the arms, but with three pulleys instead of one for greater precision, according to the creators.

The BI has several other useful features. The printhead can be upgraded with a second extruder to use two different materials simultaneously, with plans to also offer three extrusion heads in the future (multiple heads are not unheard of in 3D printers, but they are not the norm — especially not three). The printer also has a glass heat bed for the objects to be printed on, which will improve object adhesion to the build surface, the creators say. (Heated beds are required for some plastics to keep print projects from coming loose from the base and getting damaged during printing.)

There is also an option for an auto-leveling probe on the printhead, to allow the printer to measure layer heights and make adjustments to insure an object is being printed correctly. (Usually this requires manual adjustment and can't be monitored and updated on the fly.)

One interesting feature that Boots Industries is touting is self-replication: The BI v2.0 is large enough to print out the plastic parts used in its own construction. That seems to be a bit of an exaggeration, however. Most of the printer is metal or glass — and it doesn't print in those materials.

Get instant access to breaking news, the hottest reviews, great deals and helpful tips.

Follow Kevin Ohannessian at @khohannessian and on Google+. Follow us @tomsguide, on Facebook and on Google+.

Kelly Ohannessian is a freelance writer and editor. With more than 15 years of experience, she works with a focus on covering the creative aspects of the gaming industry. Her articles have appeared on Medium, Fast Company, Tom's Guide, Laptop Mag, Gamespot, and many more. Currently, she works as a manager at Brooklyn Game Lab.

-

RuthMNickerson my roomate's sister makes $71/hr on the laptop. She has been fired from work for five months but last month her pay check was $16157 just working on the laptop for a few hours. useful reference==========Jobs59.ℂOMReply

Club Benefits

Club Benefits