3D Printing Materials: The Pros and Cons of Each Type

Here's a guide to the types of materials that 3D printers use. We explain what each material is suited for as well as it limitations and trade-offs.

Here at Tom’s Guide our expert editors are committed to bringing you the best news, reviews and guides to help you stay informed and ahead of the curve!

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Daily (Mon-Sun)

Tom's Guide Daily

Sign up to get the latest updates on all of your favorite content! From cutting-edge tech news and the hottest streaming buzz to unbeatable deals on the best products and in-depth reviews, we’ve got you covered.

Weekly on Thursday

Tom's AI Guide

Be AI savvy with your weekly newsletter summing up all the biggest AI news you need to know. Plus, analysis from our AI editor and tips on how to use the latest AI tools!

Weekly on Friday

Tom's iGuide

Unlock the vast world of Apple news straight to your inbox. With coverage on everything from exciting product launches to essential software updates, this is your go-to source for the latest updates on all the best Apple content.

Weekly on Monday

Tom's Streaming Guide

Our weekly newsletter is expertly crafted to immerse you in the world of streaming. Stay updated on the latest releases and our top recommendations across your favorite streaming platforms.

Join the club

Get full access to premium articles, exclusive features and a growing list of member rewards.

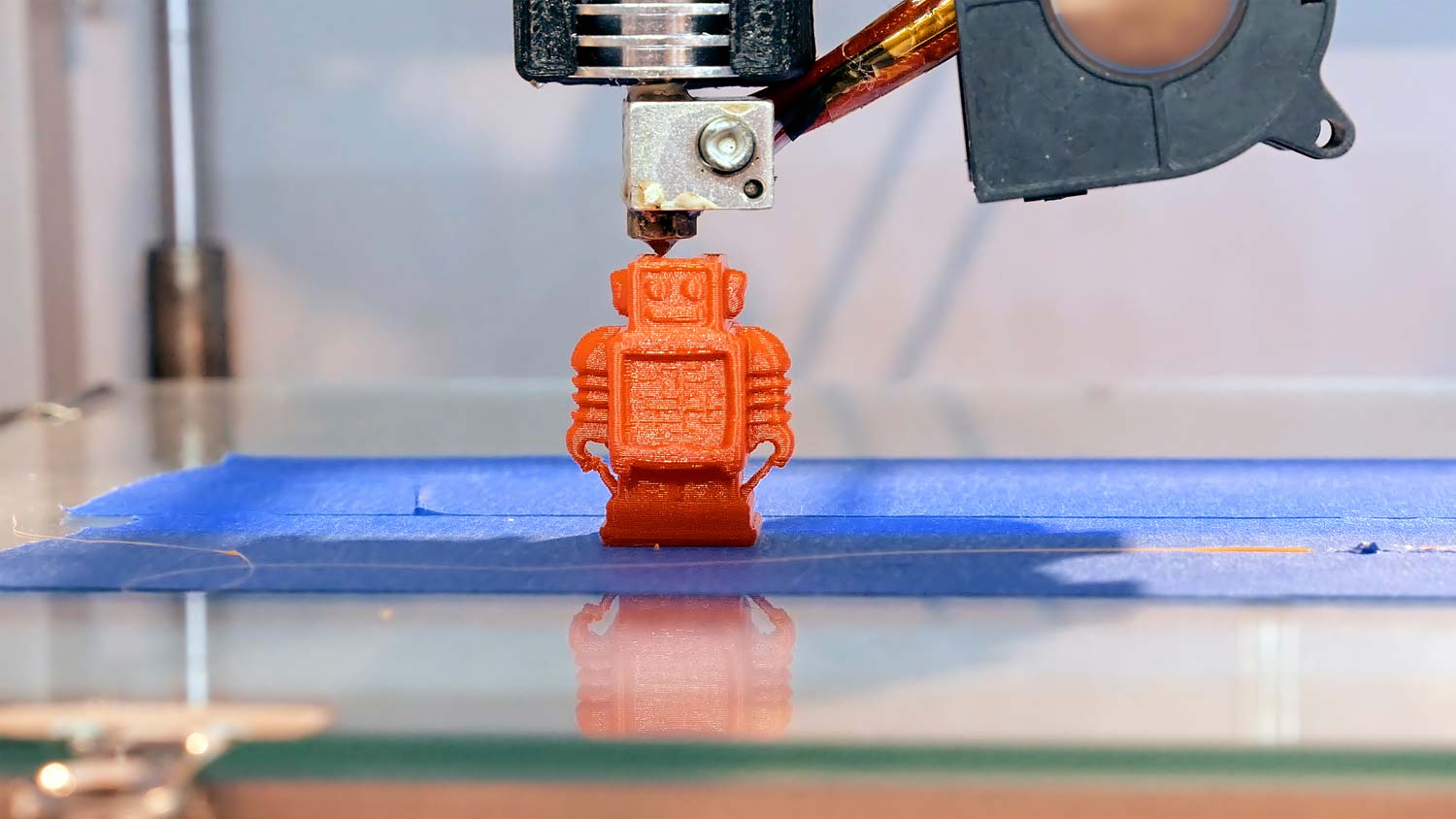

When you buy a 3D printer, it comes with a sample roll of filament to use. But what do you use when this runs out? Find out in our guide to the different types of 3D printer filament available now for fused deposition modelling (FDM) 3D printers. We'll look at the pros and cons of each material as well as which types will work with your 3D printer.

| Type | Pros | Cons | Cost per kg |

| ABS | Tough; Common; Non-toxic | High melting point; Unpleasant fumes | $20 to $50 |

| PLA | Easy to print with; Biodegradable | Prints degrade over time; Rough texture | $20 to $50 |

| PVA | Water soluble; Fairly easy to print | Expensive; Risk of toxic fumes | >$100 |

| Nylon | Tough; Inexpensive | High temperature requirement | $18 |

| HDPE | Easy to dissolve; Lightweight | High temperature requirement | $30 |

| T-Glase/PETT | Food-safe; Glass-like look | Slow to print; Heated printing bed needed | $30 |

| Wood Filament | Attractive wood-like look | Finicky to use; Requires sanding | $60 to $100 |

| Metal Filament | Attractive metal-like finish | Finicky to use; Expensive | $75 to $120 |

| Carbon Fiber Mix | Mimics carbon fiber's lightweight strength | Tough on extruders; Expensive | $50 to $120 |

| Flexible Filament | Produces flexible prints | Requires tinkering with the printer | $50 to $120 |

| Conductive Filament | Conducts electricity; Similar to PLA | Expensive; Still experimental | $70 (for a 100g reel) |

ABS

What it is: Acrylonitrile butadiene styrene (ABS) is the same plastic used in Legos. It’s tough, nontoxic and retains color well. It's also easy to shape, but tough to break, as it melts and becomes pliable at about 220 degrees C (about 430 degrees Fahrenheit).

These properties make ABS very suitable for 3D printing. You do need a large heater to reach that 220 degrees C melting point, but ABS becomes soft and pliable when heated and then sets quickly. A printer with a heated print bed is also usually needed as ABS will stick to a hot print bed.

As anyone who has stepped on a Lego will tell you, ABS is tough. It’s also water- and chemical-resistant. ABS does produce a slightly unpleasant smell when heated, and the vapor can contain some nasty chemicals, so you'll need good ventilation. Because ABS is broken down by UV radiation, it isn't suitable for long-term outdoor use, as it loses its color and becomes brittle.

Pros: Tough, impact-resistant material; Nontoxic and water resistant

Cons: High melting point; Unpleasant fumes; Not suitable for outdoor use

Good for: Gears and moving or interlocking parts

Cost: $20 to $50 per kilogram

Compatible with: Printers with extruders that heat to 220 degrees C, such as the Ultimaker 3 and TAZ Mini

PLA

What it is: Polylactic acid (PLA) is a polymer plastic, made from biological materials like cornstarch or sugarcane. It is similar to the material used in biodegradable plastic packaging and melts at between 180 and 200 degrees C, depending on other materials that are added for color and texture. PLA is a tough, resilient material with a matte, opaque quality, but it is not as tolerant of heat as ABS is. PLA begins to deform at temperatures above 60 degrees C, and it is not water or chemical resistant. There is a slight smell when it is heated, rather like microwave popcorn, but no toxic odors or vapor.

PLA is generally the preferred option for low-cost 3D printers, because it is easier to print with than ABS, as it is stickier. It will stick well to aprint base covered in white glue or blue painter's tape, which means that a heated print bed is not needed. The material is also biodegradable; like other corn- or sugar-based materials, it is slowly consumed by many common bacteria. It will last a long time in normal conditions, though. It's only when buried that it breaks down. That said, PLA is not food safe and somewhat brittle, making prints prone to shattering under stress. However, chemicals can be added that make it less brittle and more heat-tolerant, creating what some manufacturers call tough PLA.

Pros: Easier to print with than ABS; Biodegradable

Get instant access to breaking news, the hottest reviews, great deals and helpful tips.

Cons: Prints degrade over time; Rougher texture than ABS

Good for: General printing, painted miniatures.

Cost: $20 to $50 per kg

Compatible with: All FDM 3D printers, including XYZ da Vinci Mini and LulzBot Mini.

PVA

What is it: Polyvinyl alcohol (PVA) is one of a new class of 3D printing materials that are used to make supports that hold 3D prints in place. A synthetic polymer, PVA is water soluble. It melts at about 200 degrees C, and can release some nasty chemicals if heated to higher temperatures.

This is why PVA is used in 3D printing. It can be used in a standard 3D printer extruder to form parts that support other objects, and it sticks to a heated, glass print bed well. Once the printing is complete, you immerse it in water, and the PVA parts will dissolve, leaving the rest of the insoluble print behind. This makes it easier to print complex models that require supports, or even models that include moving parts. If you do use water to dissolve PVA, you'll need to properly dispose of it, as the sticky residue can clog drains. Check with your local water company for the recommended disposal method.

Pros: Water soluble; Good for supports; Fairly easy to print

Cons: Can release toxic vapors if overheated; Expensive; Requires appropriate disposal

Good for: printing complex models with PLA or ABS

Cost: More than $100 per kg

Compatible with: Standard FDM printers with multiple extruders, such as the Ultimaker 3

Nylon

What it is: The name nylon can be used for any one of a number of synthetic polymers originally created as replacements for silks. Nylon is a tough material that has a very high tensile strength, meaning that it can hold a lot of weight without breaking. It melts at about 250 degrees C and is nontoxic.

Nylon's use as relatively a 3D printing material is relatively new, but the material is becoming popular because the prints it produces are very tough and resistant to damage. It is cheap, because nylon is widely used in other industries, and it's not damaged by most common chemicals. However, nylon does require high temperatures to print: 250 degrees C is hotter than many extruders can manage. And it is harder to get it to stick to the print bed than with ABS or PLA. Generally, nylon requires both a heated print bed and white glue to stick while printing.

Pros: Tough; Inexpensive printing material

Cons: Requires high temperatures to print

Good for: Utensils that touch food, plant pots that fill with water

Cost: $18 per kg

Compatible with: FDM printers that can heat the extruder to 250 degrees C, such as the Ultimaker 3 or TAZ 6

HDPE

What it is: High-density polyethylene (HDPE, though it's also known as high-impact polystyrene, or HIPS) is used in pipes and recyclable packaging such as plastic bottles and packages (ones with the recycling ID code 2). It is a light, flexible material that sticks to itself and other materials well. HDPE is also easy to dye and mold. It melts at about 230 degrees C, but releases unpleasant fumes if accidentally heated to higher temperatures.

In 3D printing, HDPE is often used instead of ABS, as comparable prints turn out lighter and stronger than ones with ABS. HDPE does require higher temperatures to print, though, and can release unpleasant fumes if the temperature is set too high. It is resistant to most chemicals, though you can dissolve HDPE with limonene, a solvent commonly used in industrial cleaners. HDPE does have a tendency to warp: as it cools, HDPE contracts slightly, which can lead to warped prints.

Solubility in limoleme means that HDPE can also be used for printing supports for 3D prints made with other materials. After the printing is complete, the supports can be dissolved by immersing the print in limonene, which won't affect materials such as ABS or PLA. HDPE does require an extruder that can reach 230 degrees C, though, and a heated print bed.

Pros: Easily dissolved in limonene, a common solvent; Lightweight

Cons: Requires high temperatures for printing

Good for: Lightweight prints, supports for ABS prints

Cost: $30 per kg

Compatible with: Any printer that can handle ABS

T-Glase/PETT

What it is: Polyethylene terephthalate (PETT) is the chemical name of a material sold as t-glase. It is similar to polyester, often used to make clothes. It melts at about 230 degrees C, but cools into a rigid solid that resembles glass. It can be dyed while still retaining its glass-like qualities, so it is available in multiple colors. T-glase is approved for food use by the FDA, so you can use it to make dishes, cups and the like.

For 3D printing, t-glase can be printed onto a print bed heated to about 70 degrees C. It is mainly sold by Taulman, which introduced the material. While t-glase itself is strong and resilient, it has to be printed rather slowly to make sure that layers adhere properly. So printing with t-glase is typically much slower than with other materials.

Pros: Food-safe; Clear material with glass-like look

Cons: Requires heated print bed; Slow to print

Good for: Utensils, cups and others that touch food.

Cost: $30 per kg

Compatible with: FDM printers with high-temperature extruders and heated print beds, such as Ultimaker 3 and TAZ 6

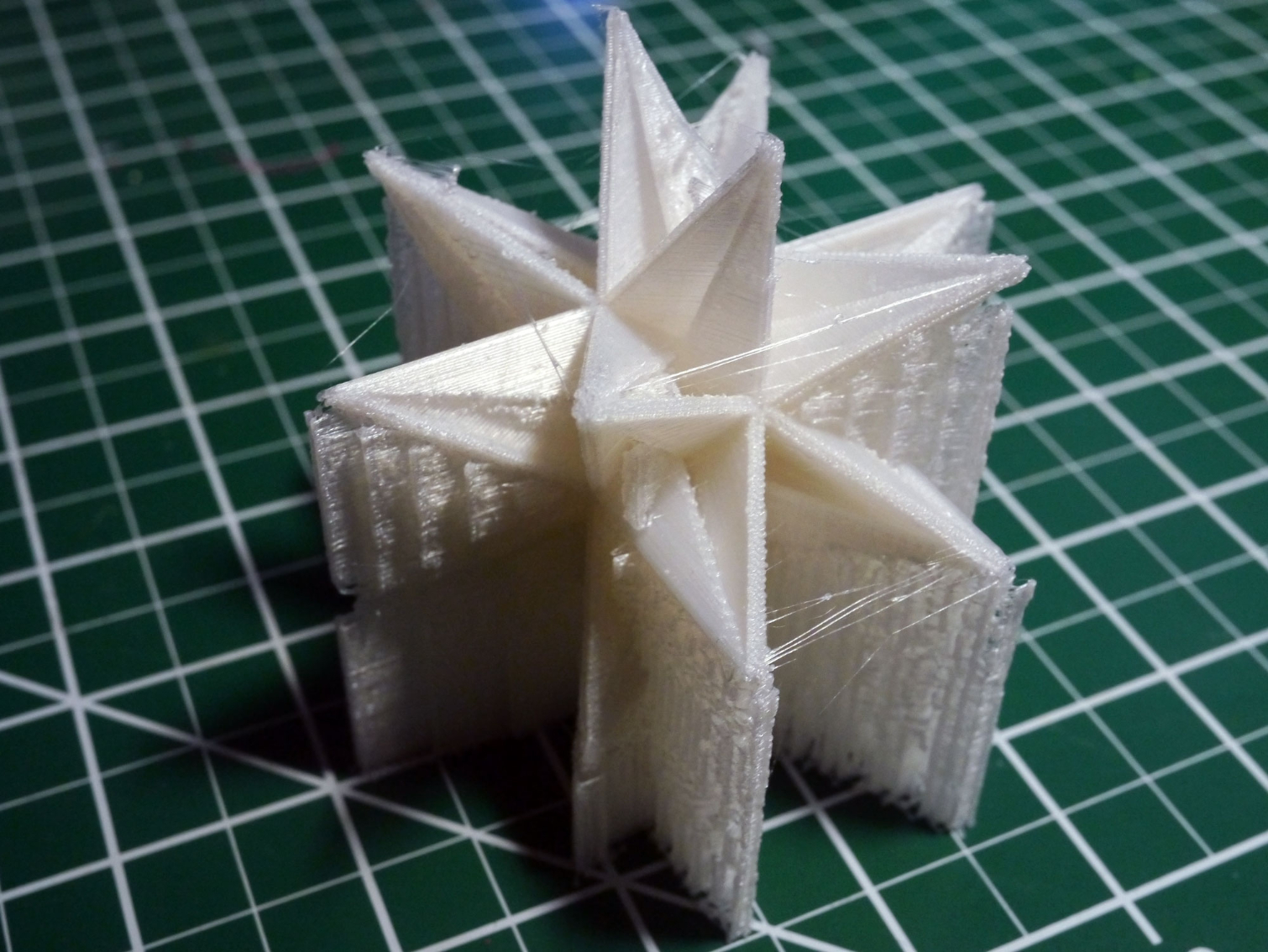

Wood Filament

What it is: These filaments are not made out of wood, but instead contain very fine wood particles combined with PLA and a polymer that binds them together. When printed and polished, the finished material can look a lot like wood. Versions are available for many different types of wood, from bamboo to ebony and mahogany. Some of these filaments allow you to change the color of the printed material by varying the temperature; at higher temperatures, the wood particles take on a darker, burned look.

These materials are printed in the same way as PLA filaments, with similar extruder temperatures and the addition of white glue to help the print stick to the print bed. The addition of the wood particles does make the process more prone to problems, though, and each different filament will require a lot of experimentation for successful prints. The material also requires extra finishing, such as sanding or mild abrasive treatment, to bring out the wood look.

Pros: Attractive, wood-like finish

Cons: Finicky to print with; Often requires sanding or other treatments to get the final desired look

Good for: Sculptures or faux-wood carvings

Cost: $60 to $100 per kg

Compatible with: Any PLA printer, but experimentation with settings will be required

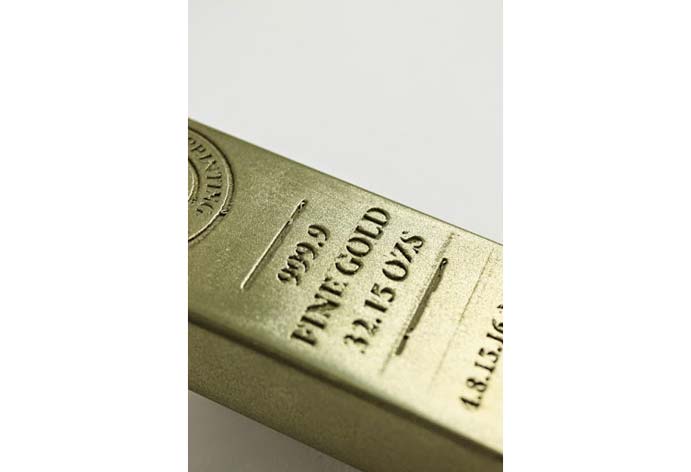

Metal Filament

What it is: Metal filaments are made of very finely ground metals combined with PLA and a polymer glue. This means that they print like PLA, but have the look and feel of metals when you polish the final print. They work on any standard printer that supports PLA filament.

Available versions include steel, brass, bronze and copper particles to create the look and feel of those respective metals. The addition of the metal does change how they print, though, so experimentation is required to find the right settings on your 3D printer. These filaments also require sanding or polishing to create the metallic look. Right off the printer, they generally look like ceramics, but brushing with steel wool ora metal polish will expose the metal particles to create the metal look.

Metal filaments are not as heavy as solid metal, so a print of a statue with a bronze filament will not weigh as much as a cast bronze version. Also, since the particles of metal are bound by the PLA and glue, these filaments won't conduct electricity.

Pros: Attractive metal finish.

Cons: Requires experimentation to find correct print settings; Expensive

Good for: Metal sculptures, figurines

Cost: $75 to $120 per kg

Compatible with: Any PLA printer, but experimentation with settings will be required

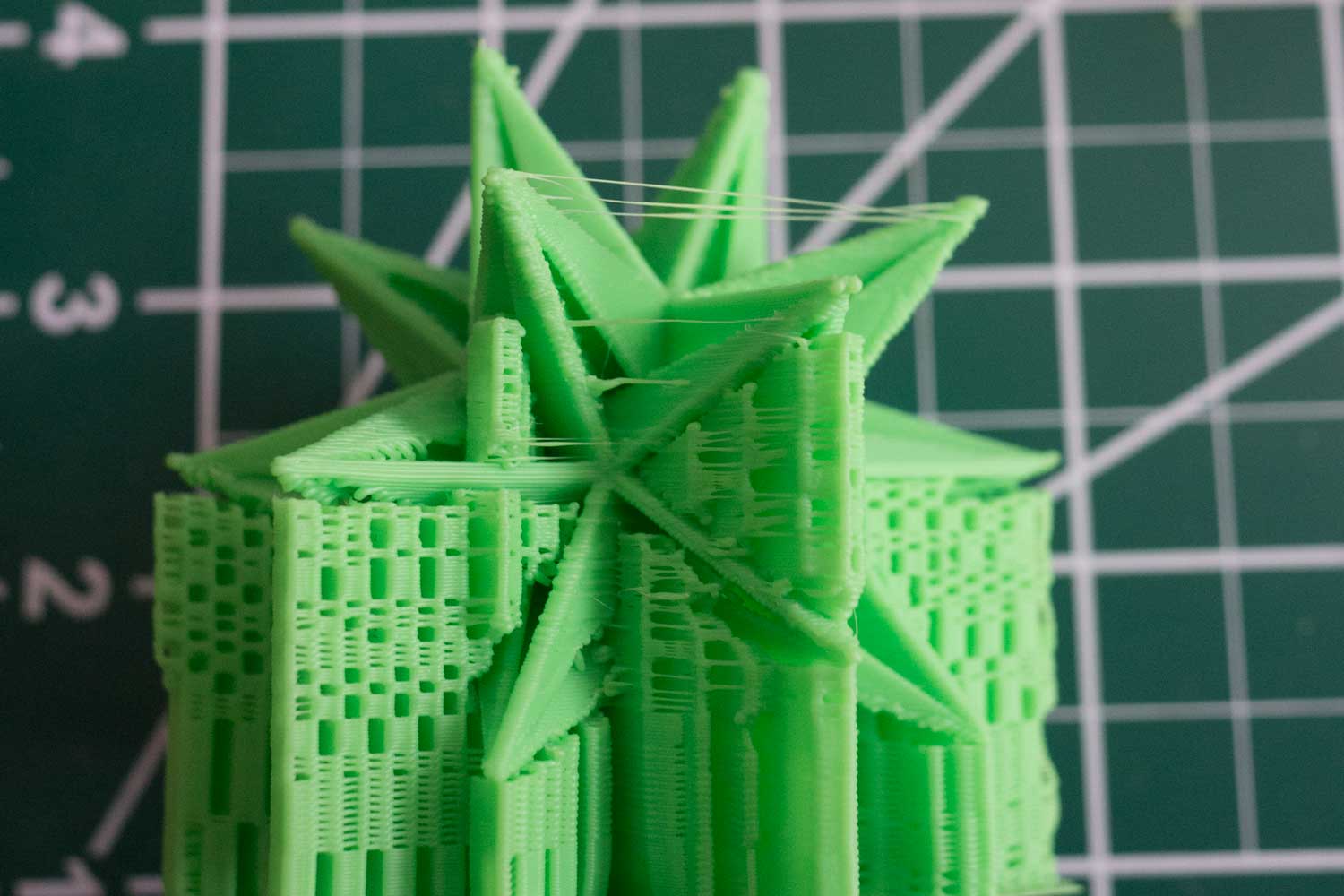

Carbon Fiber Mix

What it is: Carbon fiber filaments — like this one from MatterHackers that uses nylon, or this one from Proto-pasta that uses PLA— combine carbon fiber and the filament material to give you some of the advantages of this new material: rigidity, strength and very low weight. However, this should be used with caution. Carbon fiber is a very abrasive material that can wear away the hot end of the extruder very quickly, so you'll need to get a reinforced extruder or replace it after a few prints.

There is one company that is making true carbon fiber 3D printers: MarkForged. Its Mark Two, Onyx and Mark X printers can print using the company's own pure carbon fiber filament. But those printers aren't cheap; the Mark Two will cost you a cool $13,499, while the carbon fiber filament it uses costs $149 a reel.

Pros: Has some of the lightweight strength of carbon fiber

Cons: Can damage some extruders; Expensive

Good for: Structural prints that need to be strong and lightweight.

Cost: $50 to $120 per kg

Compatible with: Any FDM printer with a replaceable extruder

Flexible Filament

What it is: Most 3D printing materials strive for rigidity, creating prints that are strong. That's not always what you need, though, and flexible filaments like NinjaFlex, PolyFlex or TrueFlex produce rubber-like prints that can be used to make things like phone covers, flexible joints and wearable prints.

However, this flexibility also poses a problem. FDM 3D printers work by pushing the filament into the heated extruder, where it melts. You can't do that as easily if the material is flexible: it would just block up the print head. So most printers will require modification to use these flexible filaments. 3D printer maker LulzBot, for instance, offers a replacement print head, called the Flexystruder, that's designed to handle flexible filaments

Other manufacturers offer what they call semiflexible filaments, like MakerBots Flexible Filament or the new TPU95 A from Ultimaker. These aren't as rubber-like as the ones above, but they still provide some flexibility; for instance, the MakerBot filament becomes flexible when you put it in hot water, allowing you to reshape or squish a print into a tight-fitting spot before the material cools and becomes rigid again.

Pros: Produces squishy, flexible prints

Cons: Requires modification of the printer or extruder

Good for: Wearable prints, phone covers, toys

Cost: $50 to $120 per kg, plus the cost of a modified extruder

Compatible with: Any FDM printer with a replaceable extruder

Conductive Filament

What it is: New on the market are conductive filaments from companies like Proto Pasta or BlackMagic 3D that combine PLA with graphene, a form of carbon that conducts electricity. This means that you can print electric circuits directly without needing to add wires. This can be great for things like touch buttons, wearable electronics or styluses that conduct electricity.

These materials do require care when printing, as the layers of the print don’t stick to each other as well as normal PLA. The prints also tend to be brittle, and bending them can break the conductive graphene part so that they no longer conduct electricity. They are best used alongside normal PLA filament. Generally, you would print a PLA case around the parts that conduct electricity to protect it and give it more strength.

Conductive filaments are also not cheap. You’ll typically pay about $70 for a small 100g reel of this experimental new filament.

Pros: Conducts electricity; Prints like PLA

Cons: Expensive; Still very experimental

Good for: 3D printing electrical devices

Cost: $70 for a small 100g reel

Compatible with: Most printers that support PLA

Richard Baguley has been working as a technology writer and journalist since 1993. As well as contributing to Tom's Guide, he writes for Cnet, T3, Wired and many other publications.

Club Benefits

Club Benefits