News

Explore News

Latest News

RAM price crisis LIVE — latest updates on global memory shortage, expert advice and more

By Darragh Murphy last updated

Here's everything you need to know about the ongoing RAM price crisis, along with the latest updates and our expert advice on current prices on phones, tablets, laptops and more.

Meta Oakley Vanguard update adds new Garmin workout and Spotify features

By Mike Prospero published

Meta's first big update to the Oakley Vanguard smart glasses brings some pretty cool new features, including the ability to create a Spotify playlist based on what the glasses see.

You can finally cast your favorite Apple TV shows on Android — here’s how

By Josh Render published

Apple recently updated its Android Apple TV app to support Google Cast, making it easier than ever to stream content to your TV.

Every Fallout game you can play on PS5, Nintendo Switch 2, PC and Xbox Series X right now

By Rory Mellon published

"Fallout" season 2 has finally arrived on Prime Video, and here's how to play the best Fallout games on PS5, Switch 2, Xbox and PC.

Hackers are using this simple trick to take over Microsoft accounts: Don't fall for this

By Amber Bouman published

Microsoft accounts are being targeted using a common hacking technique which purposefully misspells websites and email addresses.

How to watch The Ashes 3rd Test: live stream Australia vs England, free options, start times

By Aatif Sulleyman published

The Ashes 3rd Test live streams serve up a sudden-death tie for the tourists. Here's how to watch Australia vs England from anywhere, including free options.

Amazon adds AI chatbot to the Kindle app which offers "spoiler-free" answers about your ebooks

By Scott Younker published

Amazon has added a generative AI chatbot to the Kindle app that is supposed to provide information about the book you’re reading.

OpenAI just supercharged ChatGPT images to fight Nano Banana — here's 5 prompts to try now

By Amanda Caswell published

OpenAI just upgraded ChatGPT Images with faster results, cleaner edits and better visuals. I tested what’s new — here are 5 prompts worth trying.

LG just announced its first Micro RGB TV — and it's a massive upgrade for Mini-LED

By Nick Pino last updated

Ahead of CES 2026, LG has taken the wraps off of its first-ever Micro RGB TV that looks like a serious upgrade for Mini-LED TVs.

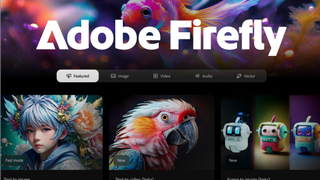

Adobe Firefly adds AI video features most generators lack — here’s what’s rolling out today

By Amanda Caswell published

Adobe is rolling out major Firefly video upgrades, including prompt-based editing, camera motion controls and a new browser video editor. Here’s what they do — and who they’re for.

Here at Tom’s Guide our expert editors are committed to bringing you the best news, reviews and guides to help you stay informed and ahead of the curve!