MakerBot Smart Extruder+ Helps 3D Printing Woes

The Smart Extruder+ is Makerbot's attempt to make its 5th generator Replicators less prone to clogs and jams.

Here at Tom’s Guide our expert editors are committed to bringing you the best news, reviews and guides to help you stay informed and ahead of the curve!

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Join the club

Get full access to premium articles, exclusive features and a growing list of member rewards.

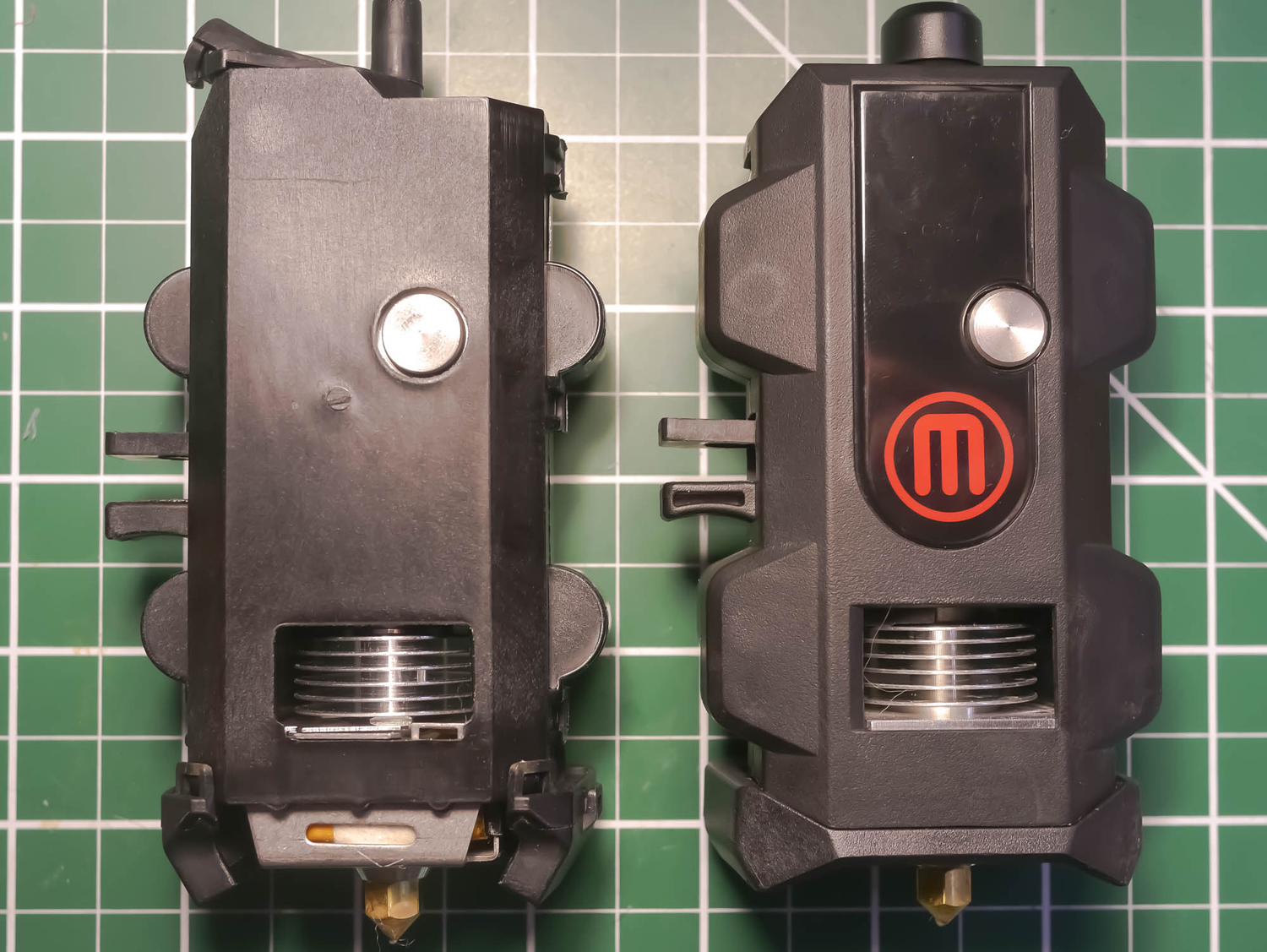

Makerbot has come up with a fix for its troubled 5th generation Makerbot Replicators — a new extruder aimed at avoiding the wear issues that have plagued many users of the 3D printer. Dubbed the Smart Extruder+, the part has been redesigned to make it easier to load filament, while a new mechanism looks to make the Replicator less prone to clogs and jams.

The Smart Extruder+ costs $199 and is slated to ship on January 18; current MakerBot customers can buy their first Smart Extruder+ for $99. The extruder comes with a 6-month replacement guarantee. That’s double the length of the warranty for older models. If the Smart Extruder+ fails during those six months, Makerbot says it will replace the extruder no matter how much filament has been used.

We’ve been testing the new Smart Extruder+ for several days on a Replicator that Makerbot supplied, and it certainly seems to deliver improved performance. We’ve had no printer jams while printing several large models. More testing will be required to see if this new extruder fixes the issues over the long term, but our initial impressions are positive.

MORE: Best 3D Printers

The new extruder is not likely to assuage the anger of many existing users, though, who will have to pay $99 for the new part. New Replicator 3D printers will continue to ship with the older Smart Extruder as well, so new buyers will have to buy the Smart Extruder+ as a separate item.

Behind the Problem

Unlike most 3D printers, the 5th gen Replicators that Makerbot released in 2014 used a removable extruder — the equivalent of a print head on a 2D printer — that was held in place by magnets. The intention was that users could swap out the extruder when a different one was needed for different materials.

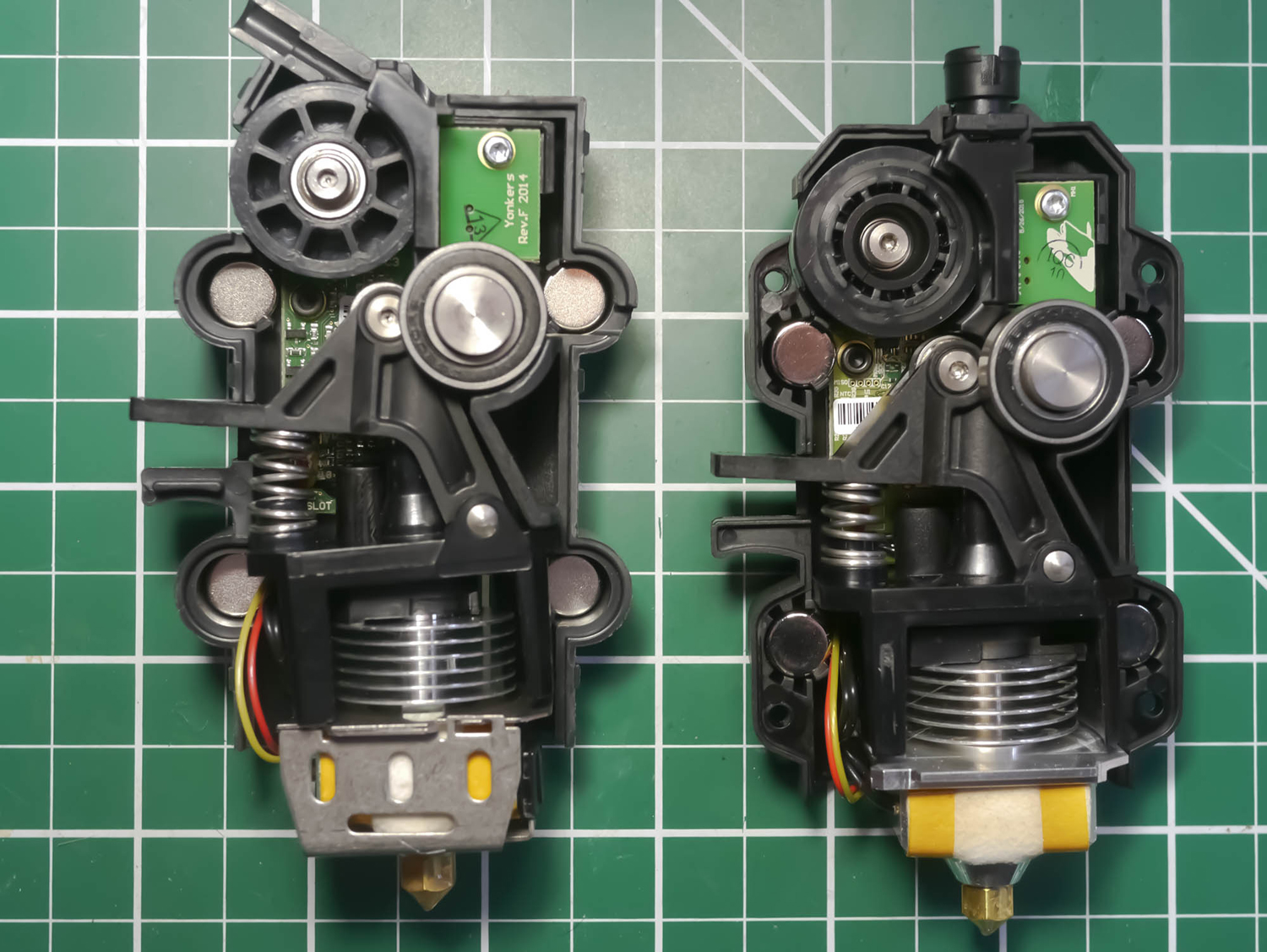

This Smart Extruder was bedevilled by problems, though. Users complained that it jammed frequently, print quality degraded over time, and the touch sensor it used to detect the print bed failed often. Perhaps most troubling for a printer designed for heavy educational use, the Smart Extruder wore out quickly, with the nozzle that the molten print material came out of getting worn after extended use.

Get instant access to breaking news, the hottest reviews, great deals and helpful tips.

In late 2015, the company acknowledged there were issues and posted a series of tips on how to avoid jams and clogs, but is still facing class action lawsuits from several pension funds over the subsequent drop in the share price of Stratasys, who bought Makerbot in 2014.

These issues were not unique to the Replicator: most 3D printers sometimes require the removal of filament jams and the replacement of the heated nozzles that the melted filament is squirted out of. However, the Replicator seals these parts inside the print head: you can’t disassemble it to to fix it yourself. Other printers put this feed mechanism behind a removeable panel and offer replacement nozzles at low cost (usually less than $25 from companies such as Lulzbot and Printrbot). Instead, Makerbot initially charged $175 for a replacement Smart Extruder. Later, it offered a $50 rebate if you returned the broken Smart Extruder.

Makerbot claims that the new Smart Extruder+ has been extensively tested, with 90 percent of those tested still working well after more than 1,200 hours of printing. It remains to be seen if this fix is enough to keep the product going in a fiercely competitive 3D printing market, though.

Richard Baguley has been working as a technology writer and journalist since 1993. As well as contributing to Tom's Guide, he writes for Cnet, T3, Wired and many other publications.

Club Benefits

Club Benefits