Fast-Charging Batteries Die a Lot Faster Too, Say Scientists

A scientific team found the reason why batteries degrade by creating the most detailed images of a battery in history.

A research team has found out why fast-charging batteries degrade a lot faster than regular ones by creating the most detailed images of a battery yet using X-ray tomography.

The scientists, led by Kenzie Zhao — an assistant professor of mechanical engineer at Purdue University — built batteries of all kinds, from phone batteries to the small button batteries you put in watches, but say that this problem affects all kinds of lithium-ion batteries, including those used in Teslas and other electric cars.

They tested them at different charging speeds before using a combination of imaging techniques and artificial intelligence to create the most detailed photos of a battery in history, going all the way down to the particle level.

The study claims that increasing battery capacity decreases its reliability. This variability in electrode particle damage is more severe in thicker electrodes — like the ones used in high capacity, fast charging batteries — and during fast-charging conditions. “The capacity of batteries doesn’t depend on how many particles are in the battery; what matters is how the lithium ions are used,” Zhao says.

How and why a lithium-ion battery degrades

Zhao and his team found out that particles near the separation between cathode and anode fail more quickly than particles far away due to the activity of the lithium ions shuffling back and forth these two parts.

“Most people regard batteries as an electrochemical system rather than mechanical system,” Zhao says on a video presenting the research, “but in fact, a battery is a mechanical system. It deforms hugely between cycles and mechanical degradation is one of the major issues [in performance degradation].”

Get instant access to breaking news, the hottest reviews, great deals and helpful tips.

A lithium-ion battery, Zhao explains, has three main components, a cathode, an anode, and a separation layer. The team looked at the cathodes at a millimeter scale using micro computer tomography at the millimeter scale. Then they kept zooming in, first using projection microscopy at the 20 micrometer scale and further into particle level imaging using a Transmission X-ray Microscope (TXM) all the way down to 5 micrometers.

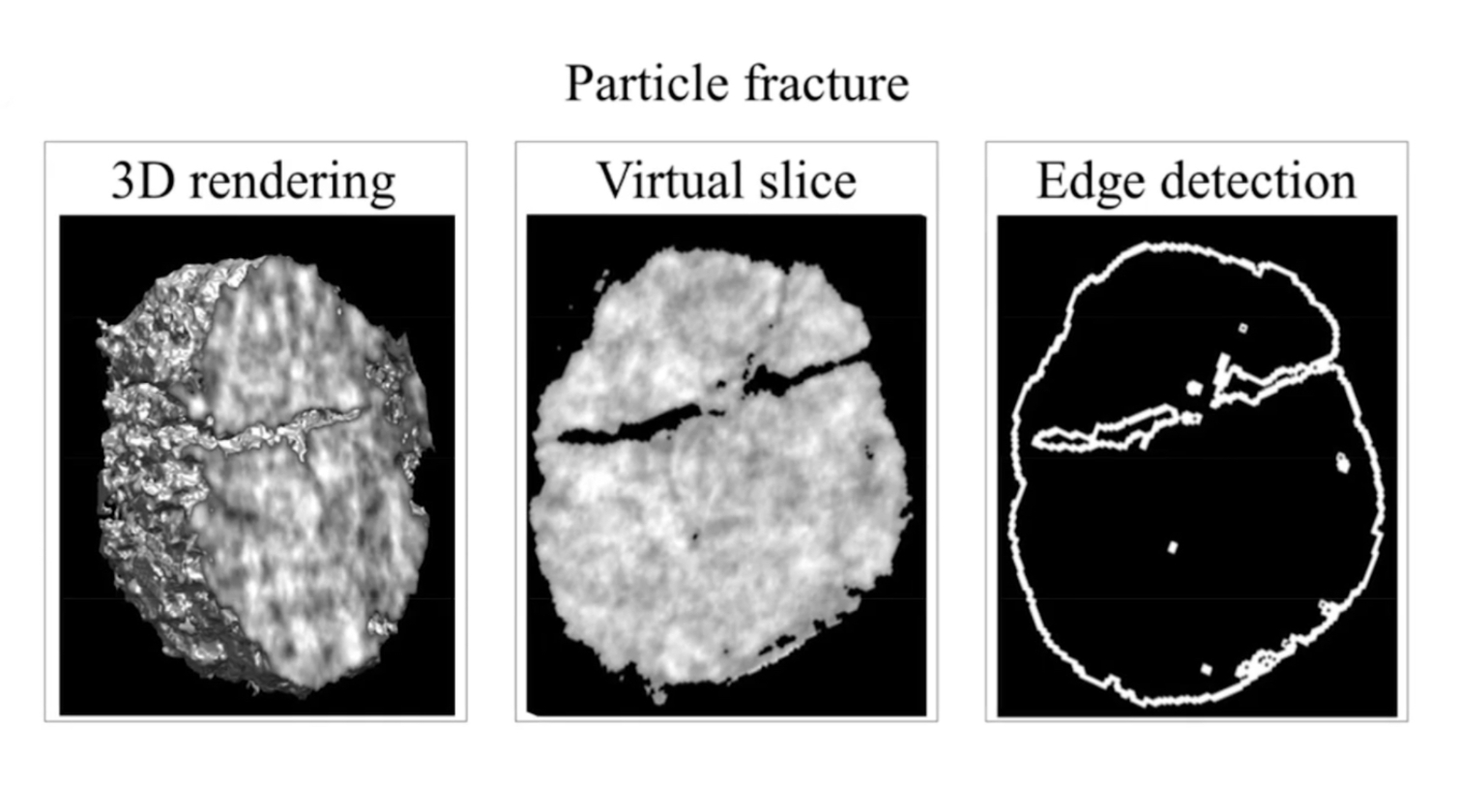

With the TXM they were able to image individual particles in great detail, creating 3D models and detecting cracks in the battery caused by the charging process on a per particle basis, as this image shows:

They used this technique to map an entire cathode, finding out that the degradation occurs faster in some particles. It doesn’t even happen in the same areas. It just happens in different spots at different speeds.

So how could you fix this? That’s up to battery manufacturers like Panasonic. The researchers weren’t trying to find a solution for the degradation. Rather, they wanted to create images that explained how the degradation occurs, how they affect the performance of batteries, and why it all happens so manufacturers can look at this data and find out solutions:

“This study highlights that the statistical mapping of the chemomechanical transformation offers a diagnosing method for the particles utilization and fading, hence could improve the electrode formulation for fast-charging batteries,” said Zhao.

Hopefully, we will see changes soon. With the insane fast-charging war raging on, batteries could soon start burning out after two months of operation.

Jesus Diaz founded the new Sploid for Gawker Media after seven years working at Gizmodo, where he helmed the lost-in-a-bar iPhone 4 story and wrote old angry man rants, among other things. He's a creative director, screenwriter, and producer at The Magic Sauce, and currently writes for Fast Company and Tom's Guide.