Best 3D printers for 2025: our top picks for beginners and experts

The best 3D printers let you create new designs and even products right from your home

Whether you're a beginner or your a habitual tinkerer, a good 3D printer is essential. From printing small parts to fix items around the home or creating entire products right in the comfort of your home, they can come in clutch so often.

But finding the best 3D printer for your needs and skill level can be tricky, especially given how many different models and designs are out there.

Lucky for you, we know a thing or two, as we've tested 3D printers for years, going all the way back to the first Makerbot.

So if you've got an ambitious creative vision that requires something more advanced, or you want to get creative and print a toy boat for your kid (he loved it, by the way), here are the best we've tested to date, replete with testing data!

The quick list

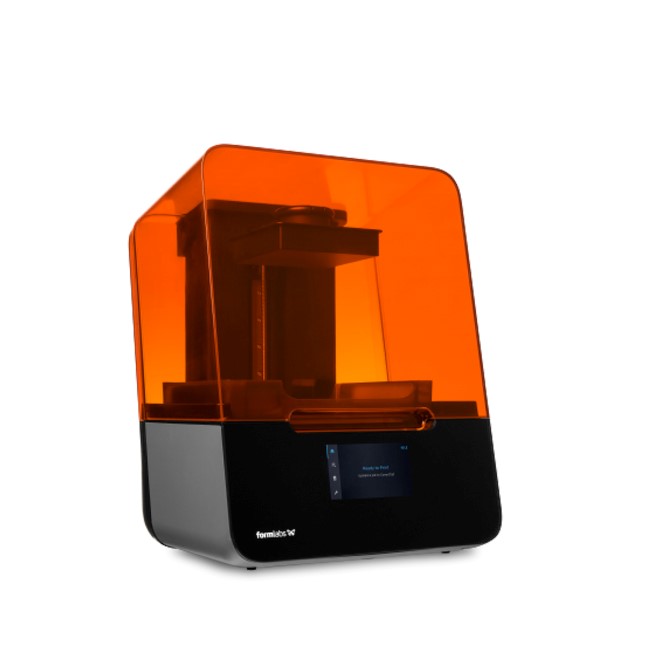

The Formlabs Form 3+ is a fast 3D printer that produces high-quality prints and is easy to use. There are a lot of different resins available but it doesn't support third-party resin.

The best 3D printer for value

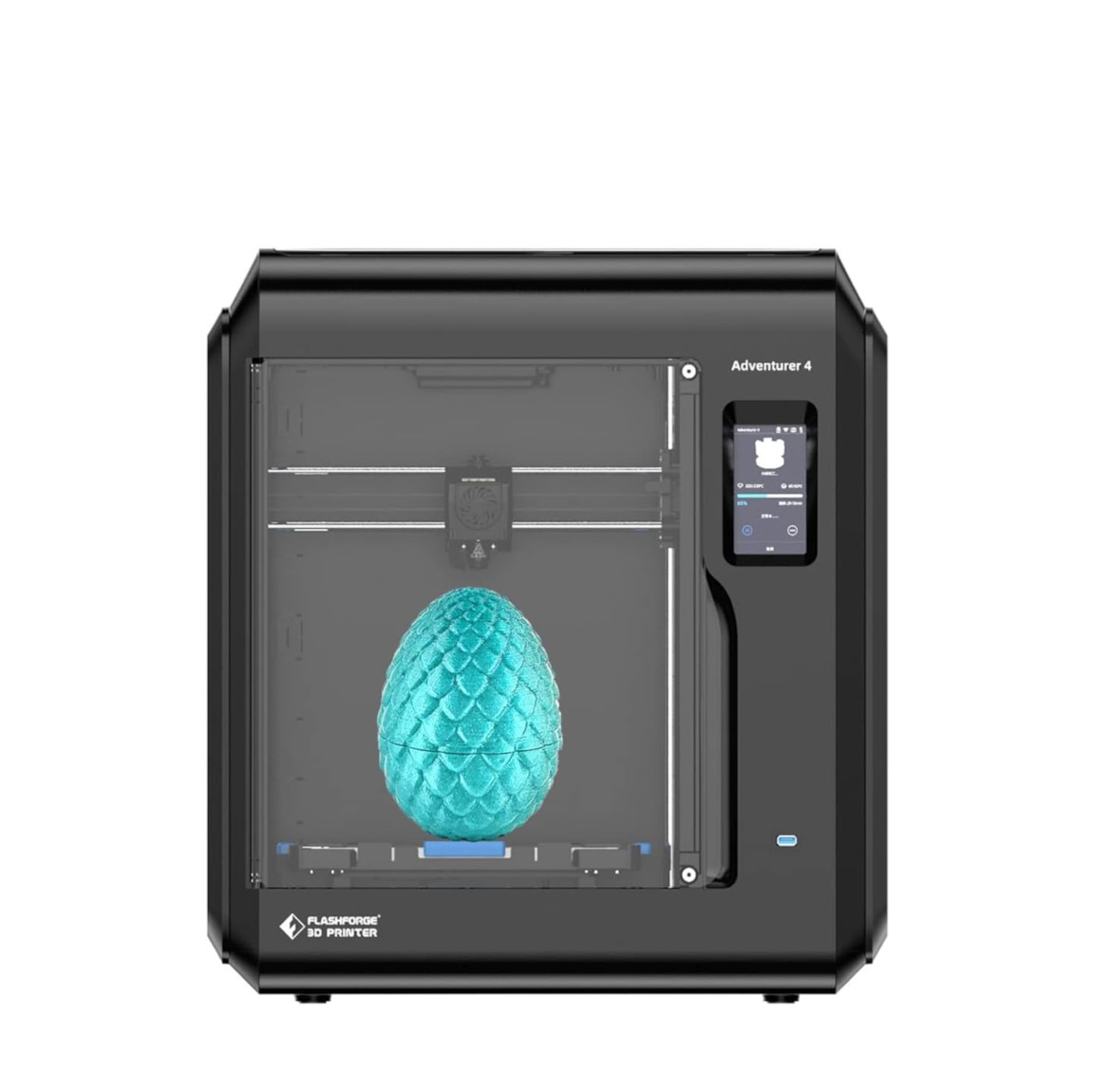

The FlashForge Adventurer 4 can handle multiple materials with ease thanks to its four swappable nozzles.

The best 3D printer for beginners

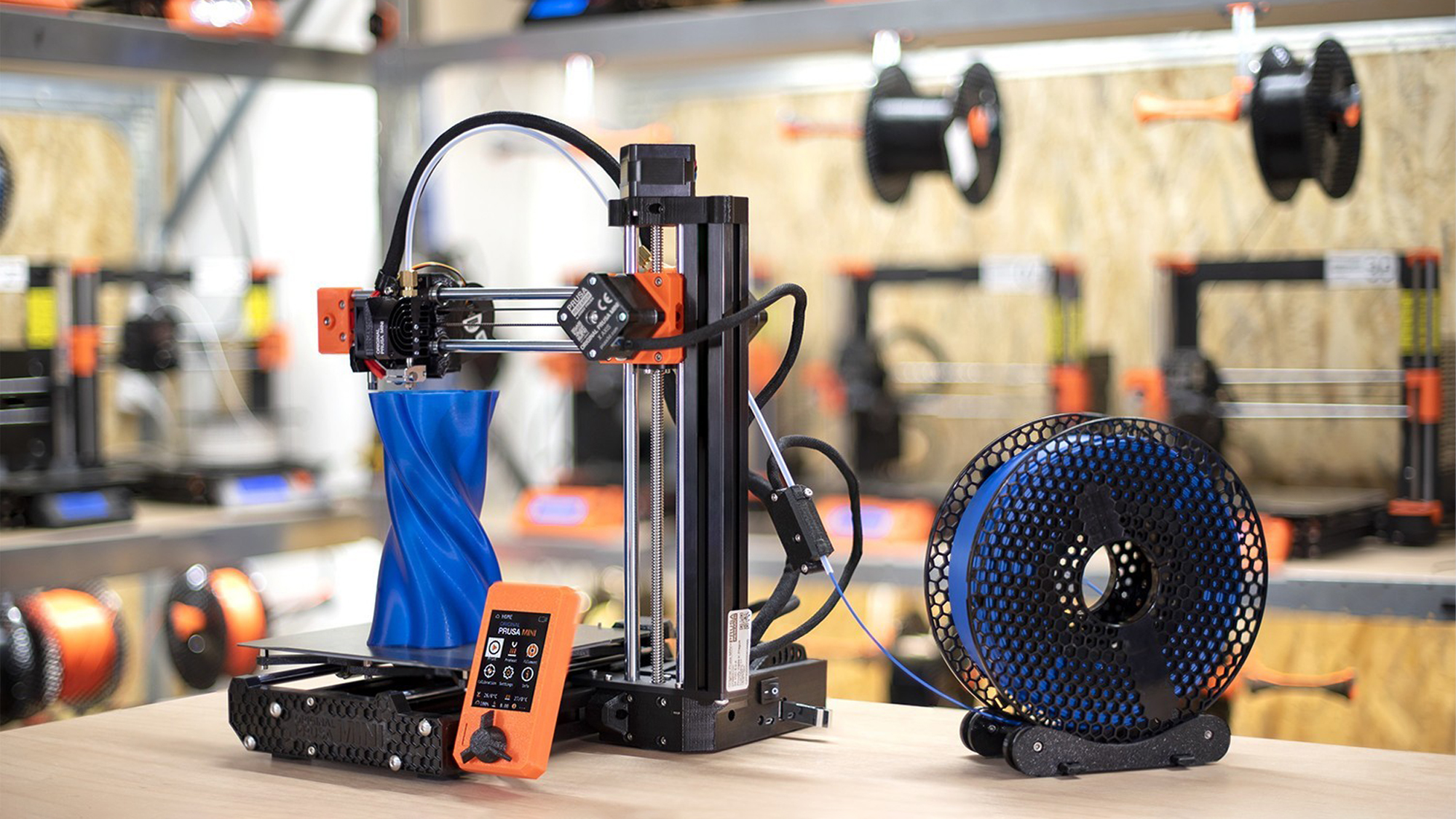

The Prusa Mini+ is great for beginners as it's simple to assemble and set up. It also comes with excellent software and has a very high print quality. The one problem is that this 3D printer can be hard to find.

Whether it's printing small items to fix things around my flat, or making bigger creations a reality to keep my nephew entertained, me and my team use 3D printers in our day-to-day. And while there are newer models then what I recommend, these deliver big on capability and value for money.

The best 3D printers you can buy today

Why you can trust Tom's Guide

The best 3D printer overall

Specifications

Reasons to buy

Reasons to avoid

Resin-based printers have seen a lot of competition from lower-priced devices in recent years, but the Form 3+ from Formlabs remains the device of choice if 3D printing is a regular part of your workflow.

The Form 3+ replaced the Form 3, formerly our top pick for resin printers. This new version churns out prints faster than before, and it's much easier to use than before. Loading up resin is simple, and a floating level sensor keeps close tabs on how much resin is in the print tray, controlling the flow so that just the right amount is used on each job. A more flexible build platform simplifies the task of removing prints.

The Form 3+ produces speedy prints, but more importantly, the quality of our test prints turned out to be superlative. A price hike puts the starting price of the Form 3+ at $3,750, so clearly, this particular model isn't for everybody. But the Form 3+ easily meets the demands of designers who need a steady flow of good-looking prints and have the means to pay for this top-tier option.

Read our full Formlabs Form 3+ review.

The best 3D printer for value

Specifications

Reasons to buy

Reasons to avoid

If you have a messy workshop with a lot of dust, the FlashForge Adventurer 4 might just be the 3D printer for you as it case is designed to keep dust out while a built-in fan and HEPA filter keeps the print bed clean. This is also a great 3D printer for those that want to have it run in the background while out and about since it has a live camera feed to show you how your print's are progressing.

While the FlashForge Adventurer 4 costs more than some other 3D printers like the Monoprice Voxel we've reviewed, you're getting a more advanced device that's also more affordable than pro-level 3D printers. It's also a bit larger at 21.7 x 19.7 x 18.5 inches but this is because the entire printing mechanism is enclosed.

The FlashForge Adventurer 4 is controlled through a simple touch-screen on the left side at the front of its case. This is easy enough to use when setting up prints but we found entering our Wi-Fi password to be a bit difficult. After a few failed attempts, we used a wired Ethernet connection to pair it with our computer and this worked flawlessly.

Read our full FlashForge Adventurer 4 review.

The best 3D printer for beginners

Specifications

Reasons to buy

Reasons to avoid

The Prusa Mini+ 3D printer is a terrific option if you're just getting started in 3D printing, though it seems to be in short supply these days. That's a shame because it offers novices reliable performance and quality prints right out of the box, even if it is more expensive than competing 3D printers for beginners.

In our testing, we found the Prusa Mini+ easy to set up, though the lack of an enclosed printing area may make this the wrong choice if you've got younger folks hanging around your workspace. Well-designed software walks you through the process of preparing your model for printing. And when it is time to print, the Prusa Mini+ performs relatively quickly at the 0.2mm quality print mode. We were pleased with the quality of all our test prints, including those that featured parts that had to fit precisely together.

Though pricier than most beginning printers, the Prusa Mini+ doesn't make you jump through a lot of hoops to get your printer calibrated and set up. We think it's a great alternative to the Monoprice Voxel.

Read our full Prusa Mini+ 3D printer review.

How to choose the best 3D printer for you

Not sure which 3D printer to pick? Here's a quick guide to help you decide.

Printer Type

There are two main kinds of 3D printers:

- FFF (Fused Filament Fabrication) printers melt plastic filament to build models layer by layer. They’re affordable, beginner-friendly, and widely used.

- SLA (Stereolithography) printers use UV light to cure liquid resin into solid shapes. They're known for high detail but usually cost more—though newer models are bringing prices down.

There are also 3D pens, a fun, low-cost option (under $100) that lets you draw in 3D using melted plastic.

Printing Materials

Materials matter to what you want to build!

- FFF printers use filaments like PLA (biodegradable), ABS (Lego plastic), nylon, TPE (flexible), and more. Filaments come in lots of colors and two sizes: 1.75mm and 3mm (not interchangeable).

- SLA printers have fewer options but can print in resins that range from rigid to soft and rubbery.

Some printers lock you into using brand-specific materials, just like your traditional inkjet printers. And others let you use whatever filament or resin you like. It pays to be careful about this!

Print Volume

The print volume depends on the print bed size and how far the head can move. Check both overall volume (we detail this in cubic inches) and individual dimensions (height, width, depth) to make sure it can handle the kinds of models you want to create.

Print Speed vs. Quality

3D printing takes time. There's no way around that.

A small model (about 3–4 inches) can take 6 to 12 hours to finish, depending on your print quality settings.

Here’s the trade-off:

- Thicker layers = faster prints, but more visible lines and less detail.

- Thinner layers = smoother prints, but it takes longer.

The best printers let you choose your balance — quick and rough or slow and polished — by offering a range of quality settings.

Price

As we've proved up above, great 3D printers don't have to break the bank.

- High-end models can cost several thousand dollars and are built for pros and heavy use.

- Mid-range options hover around $1,000, offering solid performance for serious hobbyists. But if you're happy to go back a generation, you can find printers at this level for cheaper too (like the Form 3+).

- Beginner and home printers can be found for under $300, with some solid picks even under $200 (looking at you, FlashForge Adventurer 4).

Tip: Don’t just stick to Amazon. Some brands—like Prusa or Bambu Lab—sell directly through their websites, often with better deals or bundles.

How we test 3D printers

When we review a 3D printer, we set up each model, noting how long it takes from the time to remove the printer from its packaging to calibrating the printer so that it's ready to use. We also take note of any special set-up instructions.

We look at what kind of materials a 3D printer supports and whether the manufacturer requires you to only use materials they sell.

When its time to test the printer, we have three different test models — a miniature statue of Rodin's Thinker, a complex set of planetary gears that incorporate interlocking parts, and a geometric sculpture to see well the printer can reproduce sharp edges and points. In addition to evaluating the quality and detail of each print, we also time how fast the printer works at various speeds, from draft mode to the highest-quality setting.

We also consider the software that a printer uses and the different ways you can control prints, whether it's from a computer or via a control panel on the 3D printer itself.

For more information, check out our how we test page for Tom's Guide.

Get instant access to breaking news, the hottest reviews, great deals and helpful tips.

Jason brings a decade of tech and gaming journalism experience to his role as a Managing Editor of Computing at Tom's Guide. He has previously written for Laptop Mag, Tom's Hardware, Kotaku, Stuff and BBC Science Focus. In his spare time, you'll find Jason looking for good dogs to pet or thinking about eating pizza if he isn't already.

Club Benefits

Club Benefits