Tom's Guide Verdict

3D-print enthusiasts who want to try SLA printing at low cost may be tempted by the MP Mini Deluxe. But be prepared to invest some time in getting it running.

Pros

- +

Inexpensive SLA printer resin and spare parts don't cost much

- +

Works with third-party materials

Cons

- -

Poor software

- -

Difficult to configure

- -

Printer produced lots of failed prints

Why you can trust Tom's Guide

Resin 3D printing used to be the preserve of the rich and well-resourced. This type of 3D printer uses a photopolymer-resin printing material, which solidifies when exposed to ultraviolet light, a process called stereolithography (SLA). This print offers finer details than the melted-filament approach of fused deposition manufacturing (FDM) printers like the LulzBot Mini 2.

Because SLA printing is a rather complex process often involving lasers and precise mechanics, the printers were very sophisticated and expensive. Or, at least, they used to be: Now, printers like the $599 MP Mini Deluxe are bringing this process to the home user.

You'll make some trade-offs in getting the lower price, though. The printing process is still complex and messy, and the MP Mini Deluxe has some serious shortcomings that could put off all but the most dedicated users.

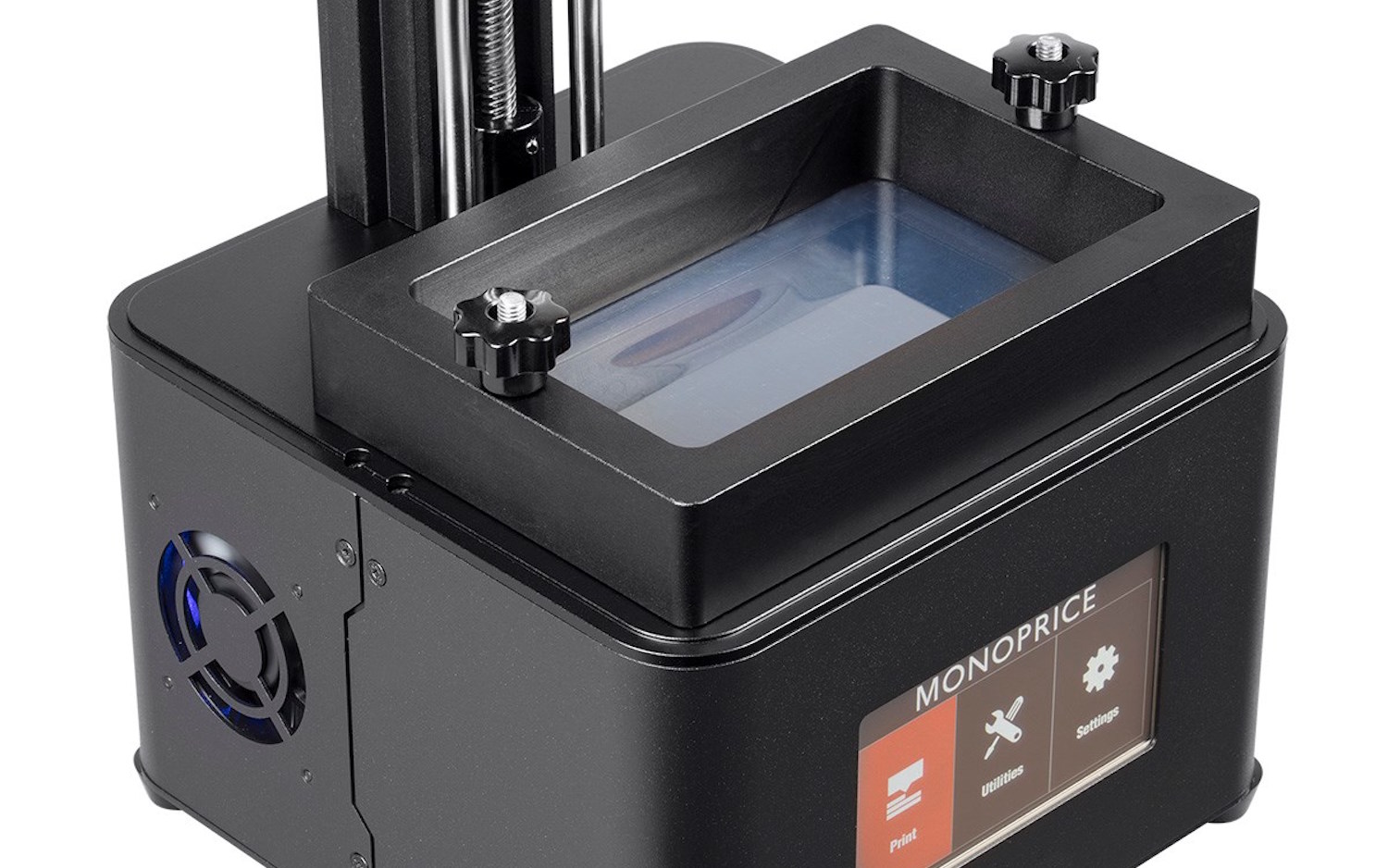

Design: Utilitarian

The MP Mini Deluxe costs so little partly because it takes a different approach than other SLA printers. More-expensive models, like the Peopoly Moai or the Form 2 use an ultraviolet (UV) laser, which bounces off moving mirrors into the transparent bottom of a vat of resin to form the print. The MP Mini Deluxe replaces the laser and mirrors with UV LEDs and an LCD screen under the bottom of the print tray.

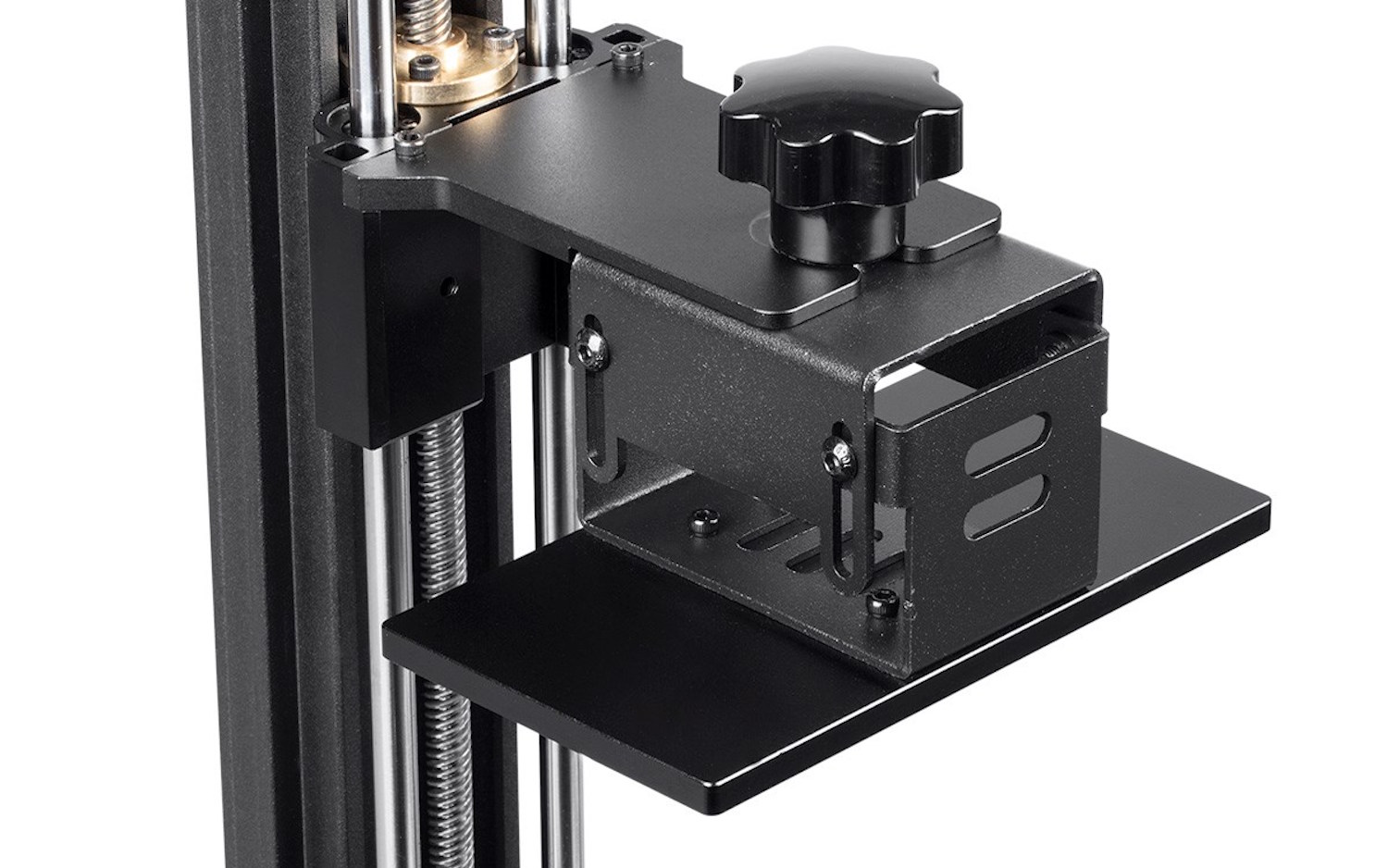

This LCD screen selectively lets the UV light through. If the screen is clear, it lets the light through and the resin solidifies. If the screen is opaque, it blocks the UV and the resin stays liquid. The printer lowers the print bed into the resin, creating a thin layer that is exposed to the light. By repeatedly raising and lowering the print head, the Mini Deluxe forms the print, layer by layer.

You can make prints only as big as the MP Mini Deluxe's 4.8 x 2.7-inch LCD screen, and this smaller size is limiting.

The downside of this process is that you can make prints only as big as the LCD screen, which, in the case of the MP Mini Deluxe, is about 4.8 x 2.7 inches. Think older iPhone size rather than the size of the iPhone XS. This rather small width is limiting; we couldn't print out test models at their usual size, as they just didn't fit into the print area.

The Mini Deluxe's print area is defined by the size of the print vat, the tray that holds the liquid resin. The base of this vat consists of a sheet of transparent FEP plastic that lets the UV light through. This base has to be replaced every 10 to 20 prints; new sheets of FEP plastic cost $4. The process of replacing these is rather involved, though, as you have to remove 18 screws that hold the retaining ring that keeps the FEP sheet in place, then reinstall these screws in a certain order to keep the FEP sheet tightly stretched. The poorly written manual that accompanies the printer fails to describe this process.

Get instant access to breaking news, the hottest reviews, great deals and helpful tips.

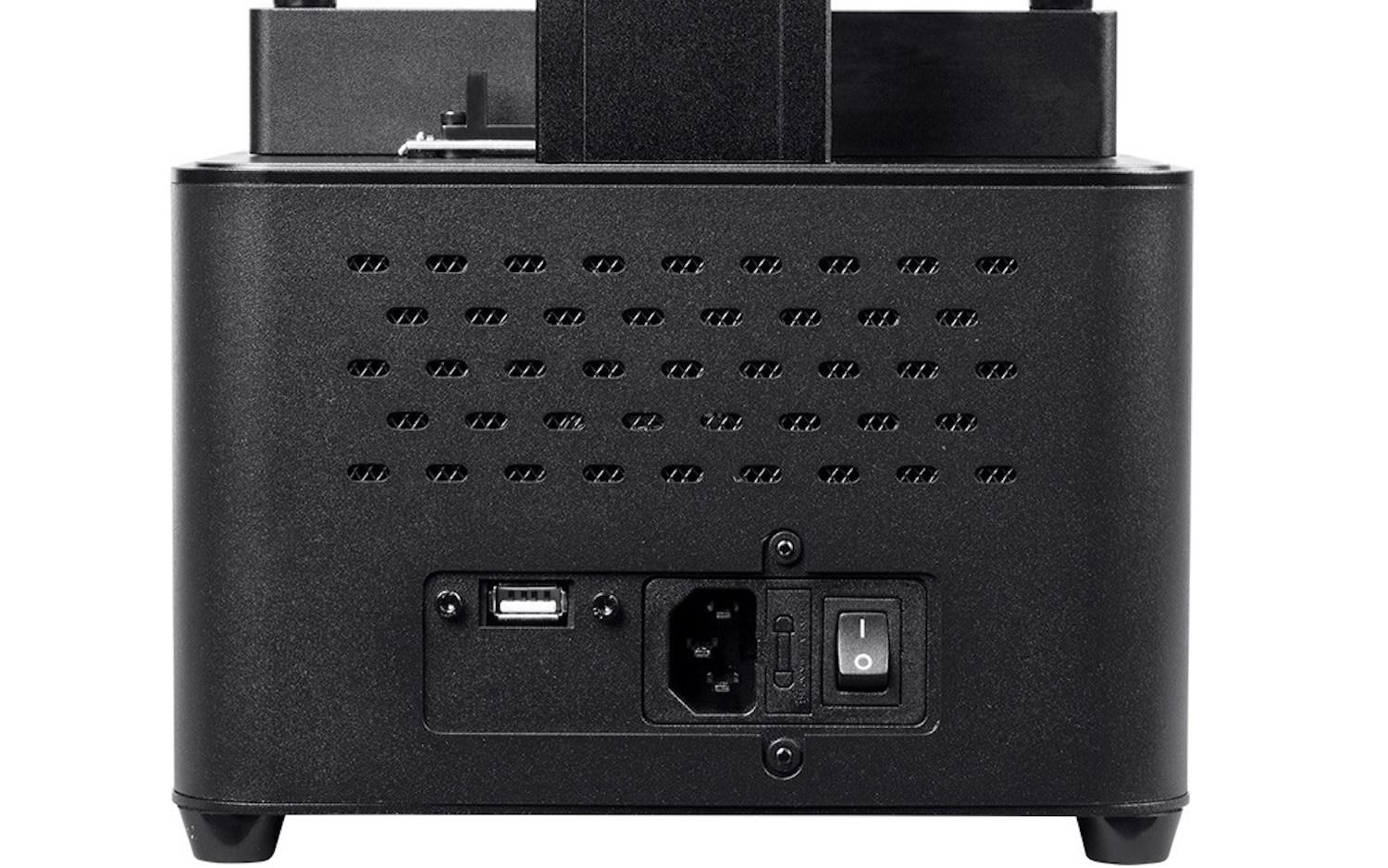

The manual also seems to be rather hastily thrown together and contains some wrong information. For instance, it describes how to connect the MP Mini Deluxe to a computer over a USB cable — except that this printer does not include the USB port that this would require. (It has only a USB socket for plugging in the USB thumb drive that the printer reads print files from.)

MORE: Best Home 3D Printers - Reviews for Beginners and Enthusiasts

While solidly built, the MP Mini Deluxe has a few rough edges. The printer comes with a large hood that covers the print area when in use, but the plastic edging on this was loose on our review model. The large LCD screen on the front of the printer is easy to see and use most of the time, but it's a little hard to see from an angle. If the printer is sitting on a table, the screen can be hard to read if you're standing over it.

Materials: Monoprice recommended, not required

The MP Mini is designed to work with resin from Monoprice, but the printer doesn't check or complain if you use other types. Monoprice does warn that doing this can invalidate the warranty, though; so, if a third-party resin leaks and fills your printer with gloppy goo, the company won't replace your device.

Monoprice's resin is pretty reasonably priced; a 250ml container will cost you about $17, or $50 for a liter. It is available in eight different colors, including back, clear and an attractive red that we used in some of our tests. That price compares well with resins for other SLA printers; Formlabs Form 2's resin, for instance, costs $149.99 a liter.

Controls: LCD and software

You control the MP Mini in one of two ways: through the Creation Workshop software that prepares your file for printing or via the LCD touch screen on the printer body that controls the printing process.

The Creation Workshop software loads your 3D model and converts it into a printable file. Monoprice offers a version only for Windows. You can use other programs, such as Cura, but they'll require a lot of customization to work with this 3D printer.

Creation Workshop is mostly easy to use, allowing you to load models in various ways, then spin, scale, move and duplicate them as required. You then create the supports, either automatically or manually, that hold the print in place during printing. Finally, the software slices the model, creating the individual layers that will be printed.

The printer's Creation Workshop software is idiosyncratic and buggy, and this sometimes leads to failed prints.

The program is idiosyncratic and buggy, which sometimes leads to failed prints. One example: When you first want to slice a model for printing, the program asks you to save the scene file, which contains the model and printing info. Fair enough. But after you save the scene file to your hard drive and slice it, you'll save the scene file again to your USB drive so that it's ready to print. Except when you try and print this file, it won't work, because the second saved file doesn't contain all of the info it needs to print; the slicing info is not saved the second time. Instead, you have to save the file directly to your USB drive and then slice it, writing out the required data to the file. Or, you can manually copy the correct file to the USB drive that plugs into the back of the printer.

MORE: 3D Printing: What to Do After You Buy Your Printer

That's just one of the numerous problems with Creation Workshop, which just feels poorly designed and constructed. We also encountered random crashes; unhelpful error messages; and seemingly random times when the program just seized up for several seconds, then started working again without explanation.

Print Process: Quiet

Once you have the print file ready on a USB drive, you may be inclined to insert the drive into the printer and start the printer running. Before you can do that, though, you have to fill the print vat with liquid resin and lower the print head into the home position.

This printer does not warn you about either of these steps; forget them, and the printer will try and print anyway, but the printing won't work. Because the MP Mini's cover completely obscures the printing area, you won't see a problem until the end or until you lift the cover and take a peek during printing. Even then, because the print platform is obscured by the walls of the print vat, you probably won't be able to see if there is a problem until the print is nearly complete.

The printer is quiet while running. The loudest noise is the quiet whirring from the fan that cools the UV LEDs on the back of the case. The resin is also a bit stinky, with a slightly bitter chemical odor. This material sticks to the hands, too, so you should use gloves when handling the resin or the finished print.

MORE: 10 Things You Never Knew Your 3D Printer Could Produce

We did have more failures with the MP Mini than we consider normal. Many prints failed to stick to the print bed, with the sticking ceasing halfway through the printing process or the prints coming out malformed, with bits missing. Although these errors became less common as I became more familiar with the printer, there were still a significant number of failures.

Print Speed: Slow

We usually test the speed of a 3D printer by creating a 4-inch-high print of "The Thinker" model. However, we were not able to print this on the MP Mini, as this model would not fit into the small print space available. For that reason, we can't compare the MP Mini's speed directly with that of other printers, but we can say that this is not a particularly fast printer. The largest print of "The Thinker" model we were able to produce (about 3 inches high) took a little more than 8 hours to produce. For context, the 4-inch version of that figure takes anywhere from about 7 hours to 11 hours on the Form 2.

Once the print is finished, you remove it from the MP Mini's print bed and rinse it in isopropyl alcohol (IPA) to remove any unfixed print resin. Again, this is a rather stinky job that requires gloves. The rinsed print should also be fixed with UV light to make sure the resin is solid throughout; a few hours in sunlight or under UV LEDs does the trick.

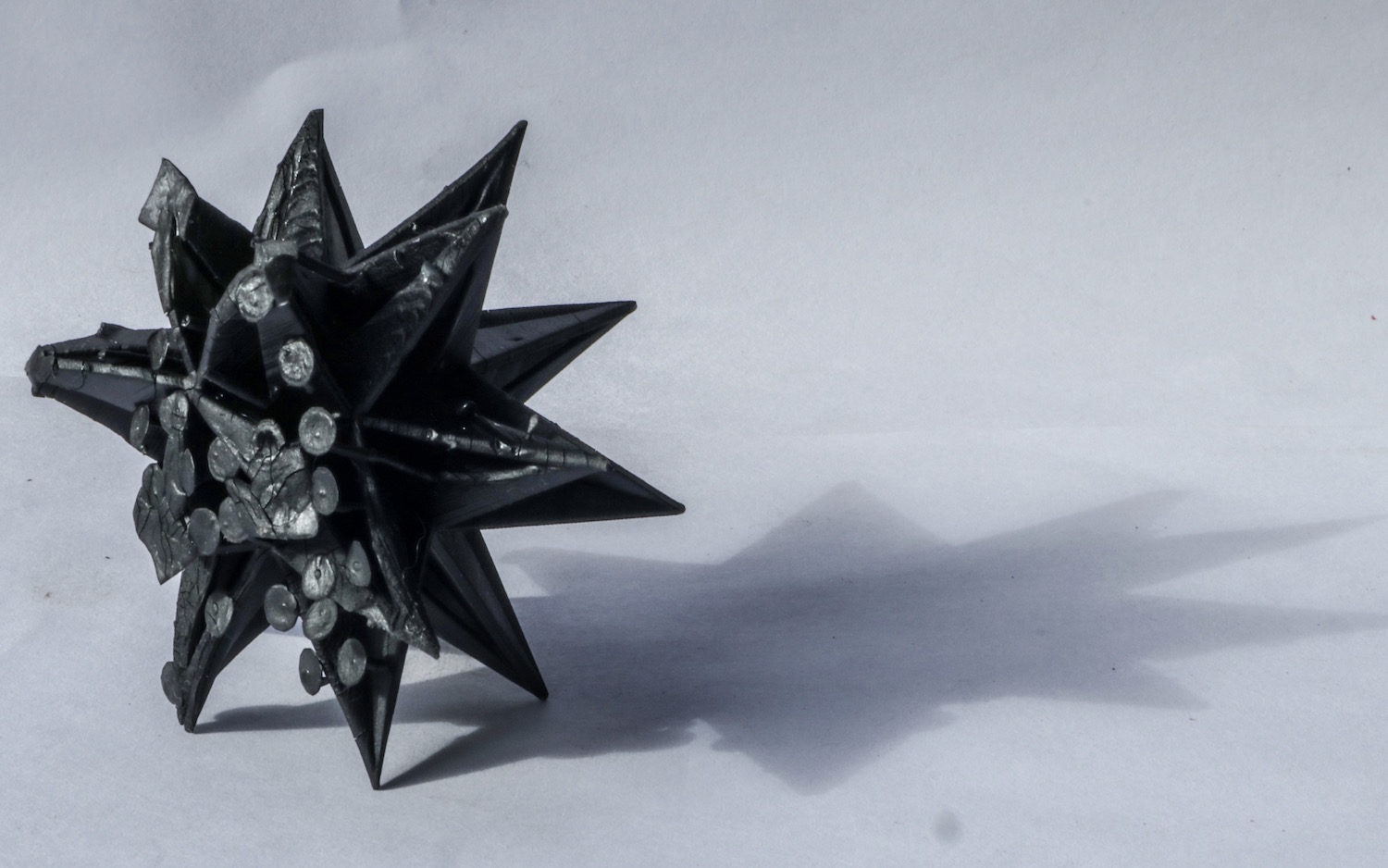

Print Quality: Good, when it works

For the prints that did come out correctly, we found that the quality of the final print produced by the MP Mini was good, with fine details and clean, sharp edges. Our geometric-sculpture test model came out well, with sharp points and clean, smooth edges.

We found that the quality of the final print produced by the MP Mini Deluxe was good, with fine details and clean, sharp edges.

We did find that the resin was too soft for our test print of a set of planetary gears to work properly, though. With this slightly pliable resin, the gears didn't mesh together well. So, this combination of resin and printer is not really suitable for engineering or other types of printing that need parts that move against each other. Monoprice does not offer a more rigid type of resin, but other manufacturers do.

Bottom Line

The MP Mini Deluxe is the lowest-cost resin printer we've yet tested, but it feels like a missed opportunity. It's a very fussy printer that requires a lot of tweaking and configuration to use, and printing is very hit and miss. Inexperienced users would probably try a couple of prints, then give up in disgust because of the poor software, poor manual, failed prints and general complications of the printer.

Monoprice's printer might appeal to a 3D printing enthusiast who has limited funds and doesn't mind putting in the work to figure out how to get the best quality out of it. Most users who want hassle-free printing will be better off spending more on an SLA printer that is better-designed and constructed like the Peopoly Moai. Or they should just stick with a cheaper FDM printer that's more reliable, like the XYZprinting Da Vinci Mini.

Credit: Richard Baguley/Tom's Guide

Richard Baguley has been working as a technology writer and journalist since 1993. As well as contributing to Tom's Guide, he writes for Cnet, T3, Wired and many other publications.