Solid State Drive Buyer's Guide

Should you consider upgrading to a solid state drive? Weigh all the pros and cons and evaluate the cost and value of doing so by reading this guide.

SLC vs. MLC, Continued

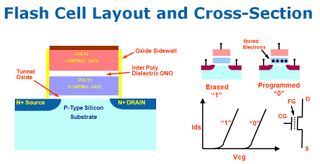

Without getting too deep or technical, think of a transistor as a two-story building. The ground on which the building is erected is the substrate, the first storey is the floating gate, and the top storey above it is the control gate. Between the substrate and the floating gate is a thin layer of oxide material. Think of the oxide as the stairs people have to go up to get from the ground to the first storey. Lastly, think of electrons as the people wanting to travel from the ground level up to the first storey. If there are no people in the first storey, then the building has been evacuated, or “erased.” If there are people up there, then you have data resident and the cell has been “programmed.”

As said earlier, SLC only requires one electron per cell; MLC requires more than one. It takes more energy to move more people from place to place. The metaphor frays a bit here, but essentially it takes more voltage to move and hold electrons in that floating gate. More voltage acts like more people stomping on those stairs, wearing them out more quickly. Given enough time, the stairs will break. The electrons effectively saw a hole in the oxide insulation layer and the floating gate can no longer reliably hold its electron(s). When this happens, the SSD controller flags the problem spot as a bad block and passes its data to another block.

Because MLC uses more electrons and requires more voltage (more sawing) to move those electrons, MLC cells will wear out faster than SLC—about 10 times faster. You might see SLC drives noted with 100,000 cycle ratings and MLC with only 10,000 cycles. If you erased and reprogrammed an MLC block once per minute continuously, it would exceed its life expectancy in about one week.

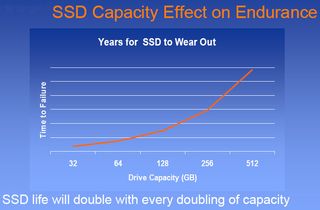

Fortunately, SSDs don’t write to the same block over and over. The drive controllers use “wear leveling” to distribute the programming cycle load evenly across the drive’s million’s of NAND memory cells. An 8Gb NAND die with 4,096 blocks, if perfectly leveled, wouldn’t start exceeding its 10,000 cycle mark for 75 years. This is why having a controller with good wear leveling algorithms is so important. Moreover, the more cells are in a drive, the more real estate there is for wear leveling. This is why there’s a nearly linear relationship between SSD capacity and drive endurance. Wear is also why enterprises have historically gravitated to SLC drives. The extra performance is good, but large corporations are positively phobic about the possibility of premature failure.

Sign up to get the BEST of Tom's Guide direct to your inbox.

Get instant access to breaking news, the hottest reviews, great deals and helpful tips.

Current page: SSD Endurance - SLC Has 10x the Lifespan of MLC - Tom’s Guide

Prev Page SLC vs. MLC - NAND Flash Memory Performance - Tom’s Guide Next Page MLC SSDs Have Drawbacks, but Are Here to Stay - Tom’s GuideWilliam Van Winkle is a freelance editor and tech journalist who has been writing for more than 20 years. His work has appeared on Tom's Guide, Tom's Hardware, Tom's IT Pro, AMD, Seagate, Computer Shopper, and more. He is also an author, writing poetry, short stories, and science fiction and fantasy books.

-

Shadow703793 Imo, I'd keep away with any SSD drive using a JMicron. Dosen't matter if the stutering,etc issues were fixed. Indylinx and Intel controllers are the best right now.Reply

Anyways, I got an X25-M G2 (OEM) for $220 @Newegg during Black Friday. -

grimjester The point about getting a small SSD for software and a larger disk for data can't be stressed enough. The price per GB looks completely different if you only need 64G. There's little difference in price between the cheapest hard drive you can get and the cheapest 500G one.Reply

An SSD is just an extra cost of $150-300. It has no practical effect on the storage space your computer has. -

Eggrenade I wouldn't say it's better than Anandtech's; there's no mention of random reads or writes, which is why performance just after startup is so good. It's also a lot less technical, which is probably better for most Tom's Guide readers.Reply -

Tomsguiderachel EggrenadeI wouldn't say it's better than Anandtech's; there's no mention of random reads or writes, which is why performance just after startup is so good. It's also a lot less technical, which is probably better for most Tom's Guide readers.Exactly :)Reply -

Tomsguiderachel nonxcarbonxThis is an even better ssd article than anandtech's ssd anthology. Nice work.Thank you. I hope it was a good fit for Tom's Guide readers' needs.Reply -

Next page broken http://www.tomsguide.com/us/ssd-value-performance,review-1455-11.html, sorry couldnt find anywhere to submit feedback. Page not working on firefox 3.5.5 (does not scroll).Reply

-

Tomsguiderachel none007Next page broken http://www.tomsguide.com/us/ssd-va 55-11.html, sorry couldnt find anywhere to submit feedback. Page not working on firefox 3.5.5 (does not scroll).I'm using the same browser and that page works for me. I will report the bug, thanks.Reply -

Tomsguiderachel TomsguiderachelI'm using the same browser and that page works for me. I will report the bug, thanks.Oh--I see that you mean the final page of the article not the penultimate page. FYI There is no content on that last page so you didn't miss part of the article.Reply -

tommysch I think Ill stick to my 4x1TB RAID 0 array for now. BTW they are ghosted each week. o_0Reply