Tom's Guide Verdict

With layers failing to stick to the print bed or each other, the majority of prints failed, and we cannot recommend this device to anyone.

Pros

- +

Attractive design

- +

Enclosed design means low noise

Cons

- -

Most prints failed completely

- -

Poor quality for 3D prints that did succeed

- -

Buggy software

- -

Random reboots on second test unit

Why you can trust Tom's Guide

EDITOR'S NOTE: Based on our review and complaints from customers, Solidoodle says it has looked into and resolved all the problems cited, repairing or replacing defective units when necessary. We will be reviewing another unit and will update this review if the results are different and we're confident they represent what consumers will get.

Who it's for: No one.

The Solidoodle Press promises a lot, with a handsome enclosed design and an appealing price just under $600. But it fails to deliver on that promise. Nearly all of our test prints — on two different units — failed completely, resulting in amorphous blobs of plastic on the printing tray. The Press also suffers from buggy software; and the design, though good-looking, has some basic functional flaws. Furthermore, similar bad results from a sister site, Top Ten Reviews, jibe with our findings, as do user forum comments and at least one review by another site (though it was more charitable in its rating).

We've been in contact with Solidoodle throughout the review process and have followed all the company's troubleshooting tips. However, the 3D printer has not functioned properly. Furthermore, at least one of the units we tested went through the company's quality checks before it was sent to us. Solidoodle maintains that our results are anomalies. We will continue to consult with the company, and if it is able to address the issues we've outlined, we may revisit this review and rating.

Promising Looks Don't Deliver

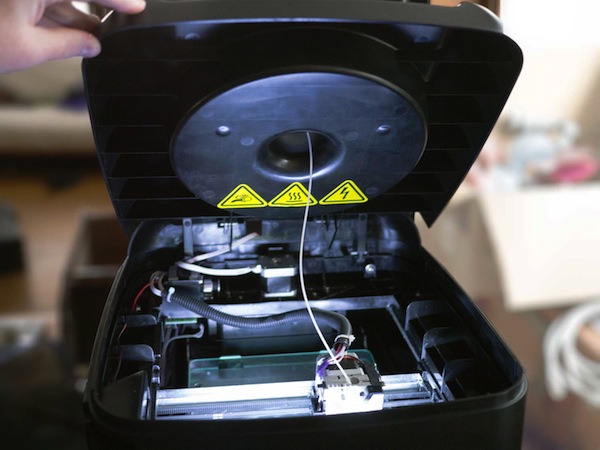

The Solidoodle Press is an impressive-looking printer, wrapped in a shiny black case that protects the printing area from drafts. There are two doors on this case: one on the top that covers the filament spool and one on the front.

This main door is partly see-through, and a light illuminates the interior so you can monitor your print. However, the print is level with the top of the see-through part of the door, so you only get a very limited view of the print during the critical early phase. That's when things are most likely to go wrong — and that they did.

MORE: Best 3D Printers

One culprit may be the filament spool that sits in a tray in the top of the printer. The filament feeds through the center of this tray, down into the printing head and all-metal extruder. This design causes the filament to bend quite a bit as the print head moves. In two instances, the print failed because the filament snapped above the print head, presumably because of this constant bending.

Get instant access to breaking news, the hottest reviews, great deals and helpful tips.

Next to the extruder is a touch sensor that the Solidoodle Press touches to various locations on the print surface, in order to judge how level the tray is.

Controls and Software: Promising but Half Baked

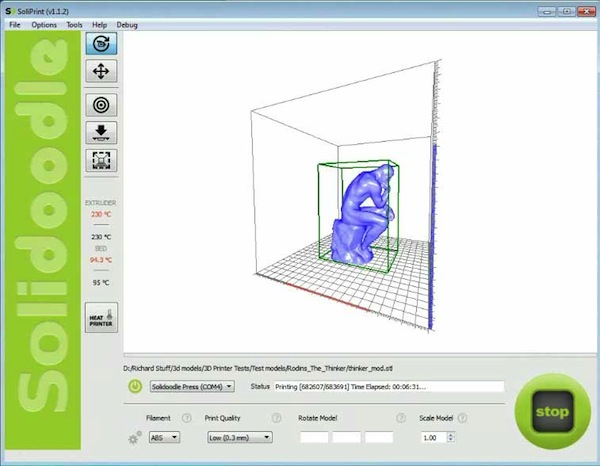

Aside from an on/off button atop the printer, everything is controlled through the included SoliPrint software. This is a simple and mostly straightforward program that has the major features a 3D printer control program needs. It can load and manipulate models, scale and rotate them to fit the build space, and provide a visual guide to the printer status, showing the temperature of both the bed and the extruder.

However, we found several problems with SoliPrint. With several 3D models, the program was unable to automatically center them in the print area — a basic function for such software. SoliPrint was also slow and laggy, sometimes taking several seconds to respond to a button press. Status messages are inconsistent, sometimes appearing in the Status window of the program and sometimes at the bottom of the screen. Overall, SoliPrint feels more like a beta test version of software, rather than the final release.

Prints Almost Always Fail

We could accept some design and software glitches if the Solidoodle Press delivered great prints. But most of the time, it delivered only blobs of plastic — no matter how many tips and tricks from the company and third-party user forums we tried. We tested two units (both supplied to us by Solidoodle), but both struggled to print, having problems such as the print failing to stick to the print bed, and layers of the print failing to stick to each other.

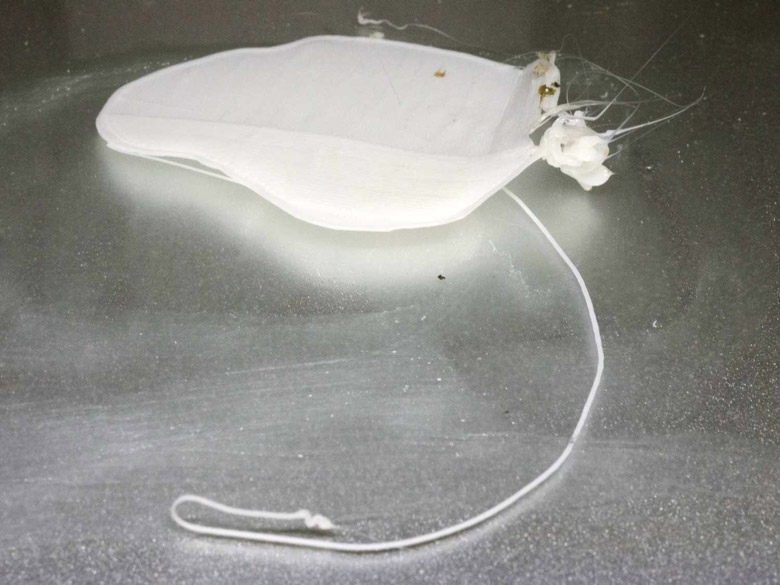

Most of our print attempts failed at the first obstacle: sticking to the print bed. The plastic that the printer extrudes didn't stick to the glass sheet that forms the print bed, and the glass sheet isn't held firmly in place, so it can easily slip during printing. (Our colleagues at Top Ten Reviews got a successful print by manually holding the bed in place.) The image below shows what should have been the Thinker — which the Press failed to print further than the first few layers. All of the other 3D printers we've tested have been able to get past this point without incident.

Below is the same print, which we made with $349 Printrbot Simple Maker.

To get the prints to stick, we tried various techniques offered by Solidoodle tech support and forum users, including using white glue, hair spray and blue painter's tape, but the majority of prints still failed to adhere.

One culprit may be the inability of the printer bed to reach an adequate temperature to make the ABS plastic stick to it. with the second unit, I set the SoliPrint software to the default print bed temperature of 95C. However, when I measured the temperature, it was only 76C. When I increased the bed temperature setting in SoliPrint to 110C, the temperature of the glass print rose to just 81C.

When the first layer did stick correctly, we often found failures in subsequent layers. The ABS print material failed to stick to the layer below, instead collecting in a goopy mess on the print head itself. On several occasions, the filament got jammed in the extruder, which required taking the extruder apart, clearing out the jam and rebuilding the device.

MORE: 3D Printing Services Reviewed: Do They Really Work?

Our second test unit had similar issues, as well as another problem: At random intervals, the printer would reboot, like someone had pulled the plug and quickly reinserted it. We were not able to discern a reason for this issue: We tried multiple power outlets, computers and USB cables, none of which prevented it.

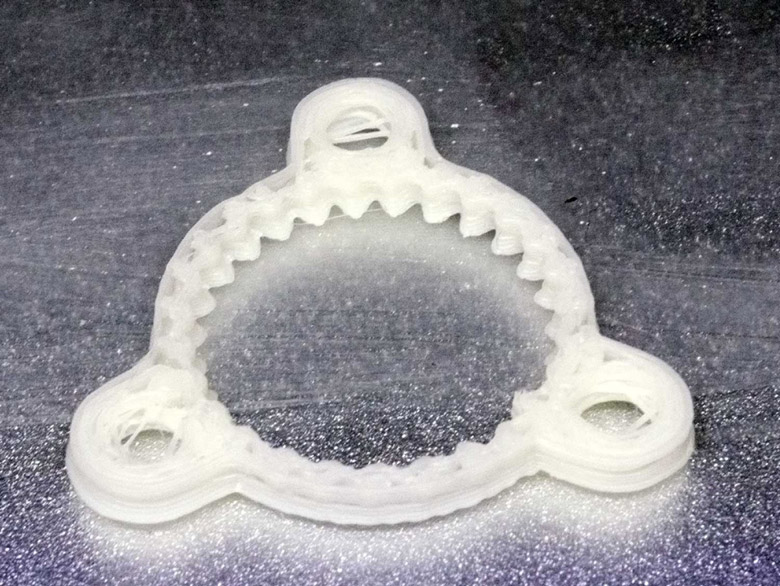

Those few print attempts that did succeed were of poor quality, with very visible layering and a lot of stray whiskers of filament in what should be clear space in the print. For example, look at the part below, which is a component of the planetary gears model we regularly test with. The three holes around the center are where the screws fit, and they should be clear with a well-defined thread. Instead, they are filled with loose filament and have no clear thread structure.

Bottom Line: Avoid this Product

3D printing is still a developing science, so we expect the odd print failure and glitch. But the Solidoodle Press had far more than its fair share of problems, and when the failed prints outweigh the successful ones by such a large margin, the product is simply unusable.

- 3D Printer Buyer's Guide 2015

- Cube 3 3D Printer Review: Quality Prints, for a Price

- Ultimaker 2 3D Printer Review: Quality Worth the Price

Follow Richard Baguley @rbaguley. Follow us @TomsGuide, on Facebook and on Google+.

Richard Baguley has been working as a technology writer and journalist since 1993. As well as contributing to Tom's Guide, he writes for Cnet, T3, Wired and many other publications.

-

JOHN YN My solidoodle press was the same except i couldn't get the printer to extrude past the initial setup. . I am now in process of getting a reworked 2nd batch product and will advise you all later if it works or not. Customer service was however on the ball.Reply